The weather is beginning to warm up with more sunshine days and temperatures in the 40oF and 50oF indicating that Spring is around the corner. While it is great news to welcome the warmth and do away with our winter jackets and warm clothing, warm weather is bad for grain storage. Winter cold weather is great for grain, and the winter period after harvest provides the best conditions for naturally cooling stored grain by ambient aeration.

We advise a three phase aeration process to get grain cooled down to 28-35oF over the winter period as follows:

- Phase 1: Fall cool down by ambient aeration

- October, 40-45oF

- November, 35-40oF

- December, 28-35oF

- Phase 2: Winter maintenance in January and February by ambient aeration cooling grain to 28-35oF

- Phase 3: Spring holding, seal fans and ventilate headspace intermittently.

At 28-35oF and less than ideal grain moisture levels for safe storage, that is, above 15% for corn and 13% for soybean, biological activity (mold and insect development) is halted and risks of grain going out of condition is very low. However, a good start to keep stored grain in good condition is ensuring that grain is dried to safe levels based on how long it would be stored before selling. For corn, we advise drying to 15% (wet basis) if you intend to store for up to 6 months (sell in the spring), and 13% if you intend to store through the warm summer into the fall or beyond one year. For soybean, store at 13% (w.b.) for up to 6 months, 12% from 6 to 12% and 11% beyond one year.

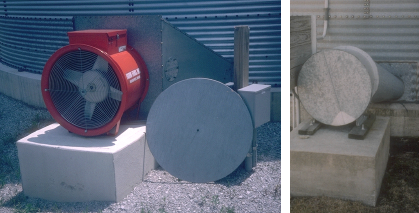

The first 6 months of storage immediately after harvest poses the least risk to spoilage, and the warm summer months poses the most risk to spoilage. We are in Aeration Phase 3, the spring holding period when fans are to be sealed (Fig. 1) to prevent air from moving naturally through the fan duct to warm up the plenum as ambient temperature rises during this period. Grain being a good insulator can hold the low temperatures it was cooled to if it is not warmed up by ambient aeration. So, in the spring, aerating the grain is not advised. For cylindrical steel bins commonly used in on-farm and off-farm storage in the Midwest, it is important to note that the air space above the grain in the bin, the headspace would warm up faster than any other region of the stored grain. This is due to radiative heat transfer from the steel bin roof, making the grain surface, which experiences these high temperatures, the most likely region where spoilage could occur. The warming of the headspace evaporates moisture from grain at the top layer of the bin increasing the headspace relative humidity during the daytime. At night-time when the headspace air cools to dewpoint, condensation, which occurs under the surface of the bin roof and possible the grain spout, could drip on to the grain surface and over time cause molding and crusting on the top grain layer. Therefore, ventilate the bin headspace at night (exchange headspace air with roof exhaust fan for 1 to 2 hours) to prevent condensation on the grain surface that could lead to crusting and spoilage. Connecting a headspace roof exhaust fan to a simple programmable on/off timer is one approach.

Another reason to check stored grain in the spring, especially the top layer for signs of crusting or molding is because any snow drifts on the top layer that came in through the eaves or snow accumulation on a leaky roof has melted and added moisture to the stored grain. Depending on the amount of snow drift or roof accumulation, the added moisture can be substantial to cause hot spot development. Hotspots in stored grain can begin to develop in the winter when we expect grain to be cold and safe in storage, and exacerbate in the spring, when the weather begins to naturally warm up the grain. A careful observation of the top layer of grain is required to identify hotspot development from the surface. A key is to carefully look for signs of corn kernel or oilseed discoloration on the surface (Fig. 2). Additionally, as temperature increases from the spring to the summer, it is advisable to increase the frequency of monitoring stored grain. In bins with temperature cables buried in the grain, it is advisable to track the change in grain temperature over time as well as the difference between the ambient temperature and that of the grain bulk. A temperature rise in the grain bulk, especially for a cable in the center of the bin, is an indicator of increased biological activity. The smell of deteriorating grain, an indicator of spoilage, can be determined by running the fans a few hours in the evening. However, don’t wait to smell spoilage before you act, it might be too late.

For those who could not dry corn to 15% in the fall, but stored at 17-18%, the warm

spring temperature offers the opportunity to dry to a safe storage moisture using natural air in-bin

systems. Begin to implement natural air drying immediately if you haven’t started already. Natural air (ambient) in-bin drying can be used to dry corn with up to 20% moisture in the spring

using airflow rates of 1-2 cfm/bu. Drying should be started when the air temperature is over 40 to 60oF and 55-75% relative humidity (RH). Also note that the fan motors and compression of the air, especially with axial flow fans, warm up the air 3 to 5oF and in doing so reduce the RH by several percent points, thereby providing good quality drying air. Again, the goal of natural air drying is to remove moisture from stored grain by using the heat energy in natural air.

Figure 3. Grain probes by Seedburo (Source: https://www.feedandgrain.com/product/seedburo-probes)

Do the following to implement natural air drying:

- Sample grain bin to determine moisture content and check for signs of spoilage on the surface

and at several depths (up to 6 ft) using a grain probe (Fig. 3). Ensure that you follow safe grain bin entry procedures by having more than one person conduct this operation. Allow time for the

headspace to be ventilated when the hatch is first opened. Sniff for signs of odors that accompany spoilage prior to entry. Also wear an appropriate dust mask (N95 grade mask). If the bin has been partially unloaded, it is advisable to use a long pole to poke for bridged grain and use a safety line to enter. For your safety, never work alone in a grain bin. You must be accompanied by one or two other persons, with one of them looking in from outside the bin. Also, never enter your bin when the unloading auger is running and enter by following appropriate “log-out/tag-out” procedures.

- Run fans continuously when ambient temperatures average 40 to 60oF with RH below 75%

while monitoring the movement of the drying front. Drying speed will depend on grain initial

moisture, airflow rate and weather. Turn off fans when it is raining (or snowing as might be the case in Indiana). Monitor the drying front by sampling the grain at several depths with a grain probe and determining moistures as an indicator of movement of the front. Also, the force required to push the probe down the grain bed is an indicator of the location of the drying front. It should be easier to push the probe through dry grain than through wet grain. Monitor the bottom layers closely to identify signs of and to prevent over drying of the bottom layers.

- Be careful not to warm up grain above 60oF if you intend to store through the summer months.

Warming grain above this temperature will increase its susceptibility to mold and increase the

rate of insect pest development.

Summary:

- If grain has been cooled to 28-35oF, seal fans to prevent rewarming of the grain bulk so that grain remains cool for a longer period. Do not aerate to rewarm grain to warm spring temperatures.

- Look for signs of surface crusting or molding on the top later of stored grain. If you need to enter the bin, be careful to follow safe entry procedures for confined bin spaces. Never enter a bin alone and ensure you have appropriate harness and personal protective equipment.

- Exchange warm humid headspace air at night using a roof exhaust fan. If grain bulk temperatures are below 40oF, do not aerate the whole bulk to prevent early rewarming in the spring.

- If grain moisture was above 15.5% when stored, consider implementing natural air drying to 15% or below depending on when you intend to sell.

- Check stored grain frequently as weather warms up. If you don’t already have one, consider getting a stored grain monitoring system using temperature and or CO2