Bean Leaf Beetle Pod Feeding on Late Maturing Soybean - (Christian Krupke and John Obermeyer)

• Late-maturing soybean may attract bean leaf beetle.

• Pod damage may result in reduced yield and seed quality.

• Green pods are more attractive to beetles than yellow ones.

• For needed treatments, be certain to follow the label's harvest restrictions.

We've heard from several pest managers about the surprisingly high numbers of bean leaf beetles in late-planted/late-maturing soybean. Green soybean fields, especially those that are behind neighboring fields in development, should be monitored for this beetle. Bean leaf beetle will be attracted to these "trap crops" and begin to feed on green pods as the foliage begins to senesce. Bean leaf beetles scar the surface of pods, but only occasionally feed through the pod to the developing beans. During pod maturation, this scar often cracks leaving an entry hole for moisture and airborne plant pathogens that may cause discolored, moldy, shriveled, or diseased beans.

Close-up of bean leaf beetle feeding on pod

It is important for pest managers to be able to predict whether economic damage will occur based on the numbers of beetles that are present and the stage of pod development (i.e., green, yellow, yellow-brown, or brown pods). Once the pods turn yellow to yellow-brown, they become unattractive and less susceptible to damage. Control is normally not warranted from this point on. Don't let higher commodity prices be the deciding factor, instead evaluate these "green" soybean fields for beetle numbers and their switch from foliage to pod feeding. Walk through fields and see if you see beetle feeding during the warmest hours of the day. If a treatment is deemed justified, be cognizant of the insecticide's pre-harvest interval which is stated in the label. In the table below are most of the common insecticides used to control bean leaf beetle and the days before one can legally harvest.

Multiple scars on pods from bean leaf beetle feeding

| Bean Leaf Beetle Insecticides and Harvest Restrictions | ||

| Product | Rate and Formulation | Days Before Harvest |

| chlorpyrifos (Lorsban)* | 1 pt. 4E | 28 |

| chlorpyrifos & gamma cyhalothrin (Cobalt)* | 19 - 38 fl. oz. EC | 30 |

| clothianidin (Belay)* | 3 - 4 fl. oz. EC | 21 |

| cyfluthrin (Baythroid XL)* | 1.6 - 2.8 oz 1 EC | 45 |

| deltamethrin (generics)* | 1.5 - 1.9 fl. oz. 1.5EC | 21 |

| esfenvalerate (Asana XL)* | 5.8 - 9.6 oz. 0.66EC | 21 |

| gamma-cyhlothrin (generics)* | 1.9 - 3.2 fl. oz. 0.5EC |

45 45 |

| imidacloprid & cyfluthrin (Leverage)* | 2.8 fl. oz. SE | 45 |

| lambda-cyhalothrin (Warrior II)* | 0.96 - 1.6 fl. oz. 2CS | 30 |

| zeta-cypermethrin (Mustang Max)* | 2.8 - 4.0 fl. oz. 0.8 EW | 21 |

| zeta-cypermethrin & bifenthrin (Hero)* | 2.6 - 6.1 fl. oz. EC | 21 |

| *Restricted Use Pesticide | ||

![]()

Click here to see the Black Light Trap Catch Report

![]()

Harvest Aids in a Not So Cooperative Year – (Glenn Nice and Bill Johnson)

Information listed here is based on research and outreach extension programming at Purdue University and elsewhere. The use of trade names is for clarity to readers of this site, does not imply endorsement of a particular brand nor does exclusion imply non-approval. Always consult the herbicide label for the most current and update precautions and restrictions. Copies, reproductions, or transcriptions of this document or its information must bear the statement 'Produced and prepared by Purdue University Extension Weed Science' unless approval is given by the author.

Not many could boast that this year was an easy growing season. Some growers have dealt with a wet spring making it difficult to put in a crop, others with a wet summer making it difficult to apply postemergence herbicides. Others decided not to use preemergence residual herbicides and were not able to put on postemergence herbicides in a timely manner. As a result, some of the weeds may have gotten away from us. If you are in this situation, no need to raise your hand, you might be thinking about using a harvest aid on that woolly field. There are a few herbicides that can be used up until the tasseling stage in corn, but most of the corn in Indiana is now at the tasseling stage or more advanced. So we are now limited to herbicide treatments that can be applied just prior to harvest to help dry down weed vegetation prior to a killing frost.

Harvest aid herbicide treatments can help in the drying down process at harvest. In these cases the corn or soybean might be ready to harvest, but the pesky weeds are not. Harvesting green weeds with your crop can make for a trying day with the combine. Nobody enjoys digging green burcucumber or morningglory vines out of the header as the sun sets and forecasted rain is on the mind. The following herbicides are labeled to be used as harvest aids.

All harvest aid applications have to be applied after the crop has matured. This is after hard dough or when soybean has dried down (brown pods or 30% grain moisture).

Aim EC [2 lb ai/gal carfentrazone] – Aim can be used as a harvest aid at 1 to 2 fl oz/A in corn and small grains; and 1 to 1.5 fl oz/A in soybean, no earlier than 3 days before harvest. Keep in mind that if you have used Aim previously this year when considering using it as a harvest aid, it can't total above 2 fl oz/A in corn for the season. Aim can aid in the dry down of velvetleaf, morningglory, pigweeds and others. Apply with a surfactant such as a non-ionic surfactant (NIS) at 0.255%v/v or a crop oil concentrate (COC) at 1 to 2% v/v. A nitrogen fertilizer such as UAN or AMS can also be added to the application. Use a minimum of 10 GPA with ground equipment and at lease 5 GPA with aerial applications to assure coverage.

Rage D-Tech [0.13 lb ai/gal carfentrazone + 3.93 lb ae/gal 2,4-D] – Rage D-Tech is Aim with 2,4-D to aid in the desiccation process. It can be used to help in drying down velvetleaf, morningglory, ragweeds, pigweeds and others in corn or small grains. Rage D-Tech does NOT have a soybean harvest aid label. Rage D-Tech can be applied at 16 to 32 fl oz/A, but like Aim, no less than 3 days and 7 days before harvesting field corn or small grains, respectively. If used previously that year the total maximum amount of Rage D-Tech is 32 fl oz/A in a year. Apply with NIS (0.25% v/v), COC or MSO (1 to 2% v/v). Do not let meat animals graze on treated plants for 14 days after application and do not feed treated straw.

Roundup Powermax [4.5 lb ae/gal glyphosate] – There are several glyphosate products that are labeled for use as harvest aids. This information is based on the Roundup Powermax label. If you are using a different glyphosate product please see your specific product's label for rates and use restrictions. Apply up to 64 fl oz/A with ground equipment or up to 44 fl oz/A by air when the corn has reached maturity (black layer) at 35 percent grain moisture or less. Apply as a harvest aid to soybean up to 3.3 qt/A when soybean are mature, after pods have set and lost all green color. Do not harvest for feed or graze treated soybean for at least 45 days after application. Applications have to be made at least 7 days before harvest for both field corn and soybean. Use of glyphosate as a harvest aid is a good method to go after perennial weeds such as pokeweed and Canada thistle.

Gramoxone Inteon [2 lb ai/gal paraquat] – Gramoxone Inteon will provide fast dry down of weeds in corn and soybean. Apply at 1.2 to 2 pt/A to corn that has matured, after black layer, at least 7 days before harvest. Soybean harvest aid applications are different for varieties. Apply to indeterminate soybean varieties approximately when 65% of the seed pods have reached a mature brown color or when seed has a moisture of 30% or less. For determinate varieties, apply when at least a half of the soybean leaves have dropped and the rest of the leaves are turning yellow. For both corn and soybean add NIS at 0.25% and COC at 1% v/v. Do not harvest corn for at least 7 days after application. Do not harvest soybean for at least 14 days after application. Mature lambsquarter and cocklebur are tolerant to paraquat and may not dry down completely.

![]()

Delayed Corn Grain Maturity & Frost / Freeze Worries – (Bob Nielsen)

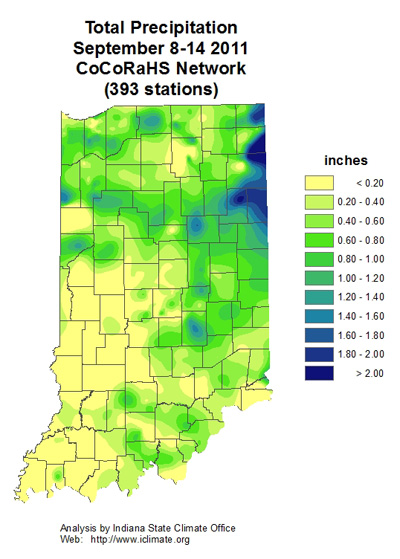

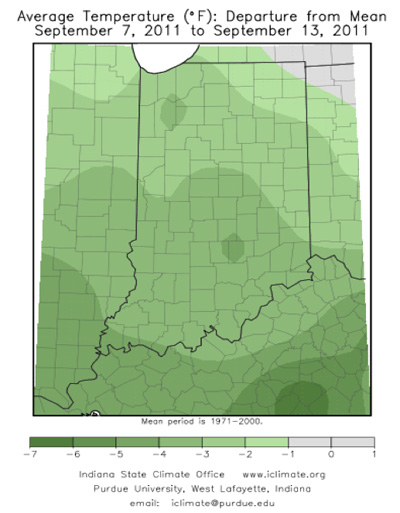

Some forecasters are speculating on the risk of frost or freeze events later this week in the upper Midwest (Andresen, 12 Sep 2011; Dutcher, 9 Sep 2011). While these forecasts suggest the risk lies mainly in areas north of Indiana, growers with late-planted corn that is not yet mature remain concerned about whether their crops will mature before a serious frost or killing fall freeze.

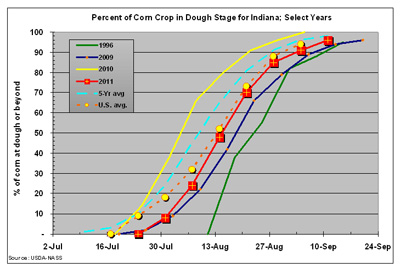

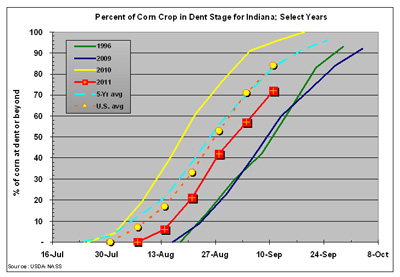

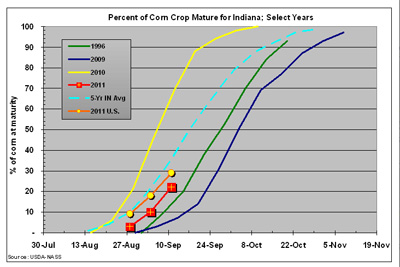

Where does Indiana's corn crop stand at the moment relative to maturity and risk of frost / freeze injury to immature corn? The current USDA-NASS estimates of the kernel development progress of the 2011 Indiana corn crop (Sept 12 report) indicates that 96% of the crop is at the dough stage of development or beyond (Fig. 1), 72% of the crop is at the dent stage of development or beyond (Fig. 2), and only 22% of the crop is physiologically mature (Fig. 3).

Fig. 1. Percentage of Indiana's corn crop at dough stage OR BEYOND; 11 Sep 2011.

Fig. 2. Percentage of Indiana's corn crop at dent stage OR BEYOND; 11 Sep 2011.

Fig. 3. Percentage of Indiana's corn crop safely mature; 11 Sep 2011.

Those numbers can be misleading because they represent the percentage of the crop at a given stage OR BEYOND. For example, when 72% of the crop is at the dent stage OR BEYOND and 22% of the crop is mature, then 50% of the crop is actually in the dent stage of development.

One needs to do similar "reverse" calculations to estimate the actual percentages of the crop that are at specific kernel stages of development. Doing so results in estimates that suggest approximately 4% of the state's corn crop remains in the milk stage of development, approximately 24% of the crop is in the dough stage, and about 50% of the crop is in the dent stage of kernel development.

An earlier article of mine offered some guidelines to help growers estimate maturity dates for corn based on current stages of kernel development (Nielsen, 2011). Those estimates are summarized in Table 1, along with estimates of possible yield losses if immature fields were damaged or killed by frost / freeze events (Carter & Hesterman, 1990). The difference between the estimates of yield losses in the last two columns of the table is based on whether the plant is completely killed or whether there is opportunity for surviving stalk tissue to remobilize stored carbohydrates to the immature grain before kernel black layer occurs.

Given the estimated percentage of the state's corn crop yet in the dent stage of development or younger, the significance of an early-occurring fall frost or freeze event in the next few weeks should not be underestimated.

Keep your fingers crossed!

| Table 1. Kernel developmental stages and estimates of yield loss if damaged by frost or freeze prior to maturity. | ||||

| Kernel Stage | % of Indiana Crop (11 Sept 2011) | Approx. Days to Maturity | Est. Yield Loss If... | |

| Only Leaves Killed | Death of Whole Plant | |||

| (1) | (2) | (2) | ||

| Milk (R3) | ~4% | 44 - 51 | >35% | >60% |

| Dough (R4) | ~24% | 35 - 40 | ~35% | ~55% |

| Dent (R5) | ~50% | 19 - 24 | ~27% | ~41% |

| Half-milkline | ?? | 10 - 14 | ~5% | ~12% |

| Mature (R6) | ~22% | 0 | 0% | 0% |

R3 = White or yellow kernels w/milky fluid |

||||

Related Reading

Carter, P.R. and O.B. Hesterman. 1990. Handling Corn Damaged by Autumn Frost (NCH-57). Purdue Extension. [online] http://www.ces.purdue.edu/extmedia/NCH/NCH-57.html [URL accessed Sep 2011].

Nielsen, RL (Bob). 2008. Grain Fill Stages in Corn. Corny News Network, Purdue Extension. [online] http://www.kingcorn.org/news/timeless/GrainFill.html [URL accessed Sep 2011].

Nielsen, RL (Bob). 2011. Predicting Corn Grain Maturity Dates for Delayed Plantings. Corny News Network, Purdue Extension. [online] http://www.kingcorn.org/news/timeless/RStagePrediction.html [URL accessed 12 Sep 2011].

![]()

Field Drydown of Mature Corn Grain – (Bob Nielsen)

Weather conditions strongly influence in-field grain drydown.

Plant characteristics can also influence in-field grain drydown.

Early grain maturation usually means faster in-field grain drydown.

Later grain maturation usually means slower in-field grain drydown.

The rate of field drydown of corn grain and the resulting grain moisture content at harvest obviously influences growers' cost of artificially drying the grain after harvest. An early drydown of the crop also facilitates early or at least timely harvest of the crop prior to the colder and, often, wetter conditions of late fall.

Kernel moisture content decreases as the kernel develops through the blister stage (~ 85% moisture), milk stage (~ 80% moisture), dough stage (~ 70% moisture), dent stage (~ 55% moisture), and finally physiological maturity (~ 30% moisture). Prior to physiological maturity, decreases in kernel moisture occur from a combination of actual water loss (evaporation) from the kernel plus the continued accumulation of kernel dry matter via the grain filling process. After physiological maturity (identified by presence of the kernel black layer), percent kernel moisture continues to decrease primarily due to water loss from the kernel.

Weather & Timing of Grain Maturation

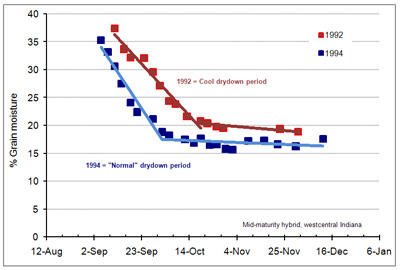

Grain moisture loss in the field occurs at a fairly linear rate within a range of grain moisture content from about 40 percent down to 15 to 20 percent, and then tapers off to little or no additional moisture loss after that. The exact rate of field drying varies among hybrids and years. Figure 1 illustrates changes in grain moisture content over time for an adapted medium maturity hybrid in two years with different temperature patterns following physiological maturity.

Fig. 1. Example of field drying progress of a mid-maturity corn hybrid in 2 years with different temperature patterns.

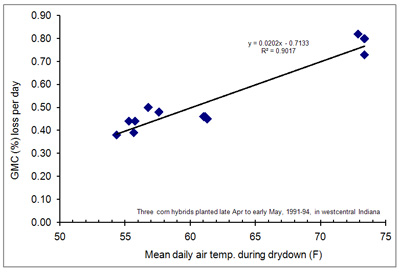

Fig. 2. Average daily grain moisture loss (percentage points/day) relative to average daily air temperature during the drydown period for three corn hybrids planted late April to early May, 1991-1994, westcentral Indiana.

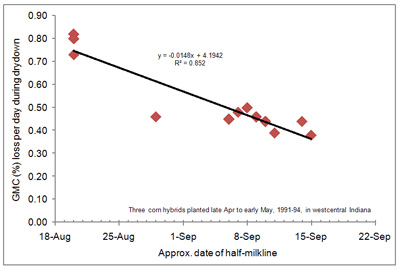

Fig. 3. Relationship between field drying rate and the date at which the grain nears maturity (half milkline) for three corn hybrids planted late April to early May, 1991-1994, westcentral Indiana.

Field drying of mature corn grain is influenced primarily by weather factors, especially temperature and humidity/rainfall. Simply put, warmer temperatures and lower humidity encourage rapid field drying of corn grain. Figure 2 illustrates the relationship between the average daily temperature over the entire drydown period and the average daily rate of field drying over the entire drydown period.

Because grain drydown rates are greater when the drydown period is warmer, it stands to reason that a corn crop that matures in late August will dry down faster than one that matures in mid-September. In fact, there is a close relationship between the date when the grain nears physiological maturity (half-milkline or 2 to 3 weeks prior to kernel blacklayer) and the subsequent average daily drydown rate. Average daily drydown rates will range from about 0.8 percentage point per day for grain that nears maturity in late August to about 0.4 percentage point per day for grain that nears maturity in mid- to late September (Fig 3).

Bear in mind that grain moisture loss for any particular day may be quite high or low depending on the exact temperature, humidity, sunshine, or rain conditions that day. It is not unheard of for grain moisture to decline more than one percentage point per day for a period of days when conditions are warm, sunny, windy and dry. In contrast, there may be zero drydown on cool, cloudy, rainy days.

Weather-Related Crop Stress and Field Drydown of Grain

Folks often question whether field drydown will occur "normally" when weather-related stress damages the crop prior to physiological maturity or causes premature death of the plants. Examples of such weather stress include that due to severe drought plus heat, severe damage by hail, and frost or killing freeze events prior to physiological maturity.

The answer in all cases is essentially "yes", but this requires a bit of explanation.

A lingering stress such as drought or foliar disease (e.g., gray leaf spot) that occurs during the latter stages of the grain filling period typically causes premature death of the plants, smaller kernels, AND premature formation of kernel black layer. The latter two factors usually result in earlier drydown of the grain to the extent that grain moisture content in severely affected areas of a field is usually drier at harvest than lesser affected areas. The fact that grain drydown of the "prematurely mature" grain begins earlier usually means it occurs in relatively warmer time periods and so grain drydown rates per day are higher than would be expected if the grain had matured "normally" at a later date. However, the rate of grain drydown is "normal" for the time period in which the grain is drying.

The effects of a sudden single stress event like hail or lethal cold temperatures prior to physiological maturity often create an optical illusion of sorts. Because leaf or plant death of an immature crop may occur quite rapidly in response to severe hail damage or lethal frost / freeze events, the moisture content of the yet immature grain will "appear" to be quite high given that the appearance of the now dead plants would seem to suggest the crop was "mature". In fact, subsequent field drydown of the affected grain will occur fairly normally relative to their immature stage of development (Hicks, 2004). The appearance of the dead plants gives the illusion that drydown was slowed by the damage from the hail or frost/freeze.

Corny Trivia: Grain in fields severely damaged or killed by severe stresses during the grain filling period will always reach physiological maturity (kernel black layer). The significant reduction or complete cessation of photosynthate availability due to damaged or dead plants will eventually lead to the death and collapse of the placental tissue at the tips of kernels that develops into the so-called "black layer."

Hybrid Variability for Field Drydown

Hybrid variability for the rate of grain moisture loss during post-maturity drydown and the eventual grain moisture content at harvest are of great interest to grower and seed industry alike. Growers desire hybrids with superior yielding ability (maximum gross income) that also dry very quickly in the fall (minimum drying or grain shrinkage costs).

The seed industry uses grain moisture content data to assign relative hybrid maturity ratings on the basis of relative moisture differences among hybrids at harvest (Nielsen, 2011). Two hybrids that differ by one "day" of relative maturity will typically vary by about one half percentage point of grain moisture content (an average daily loss of moisture) if planted and harvested on the same days. Recognize that relative hybrid maturity ratings are most consistent within, not among, seed companies.

When weather conditions are great for rapid grain drydown, hybrids tend to dry at fairly similar rates. When weather conditions are not favorable for rapid drydown, then hybrid characteristics that influence the rate of grain drying become more important.

Researchers have identified the following traits or characteristics as ones most likely to influence grain drying in the field. The relative importance of each trait varies throughout the duration of the field drydown process and, as mentioned earlier, is most influential when weather conditions are not conducive for rapid grain drying.

Kernel Pericarp Characteristics. The pericarp is the outermost layer of a corn kernel (botanically; the ovary wall). Thinner or simply more permeable pericarp layers have been associated with faster drying rates in the field.

Husk Leaf Number. The fewer the number of husk leaves, the more rapid the grain moisture loss. In fact, modern hybrids have fewer husk leaves than those commonly grown years ago.

Husk Leaf Thickness. The thinner the husk leaves, the more rapid the grain moisture loss.

Husk Leaf Senescence. The sooner the husk leaves senesce (die), the more rapid the grain moisture loss.

Husk Coverage of the Ear. The less the husk covers the tip of the ear, the more rapid the grain moisture loss.

Husk Tightness. The looser the husk covers the ear, the more rapid the grain moisture loss.

Ear Declination. The sooner the ears drop from an upright position after grain maturation to a downward position, the more rapid the grain moisture loss. In particular, husks of upright ears can "capture" rainfall.

Final Trivia For Coffeeshop Conversations

Interestingly, there is little, if any, documented evidence that moisture loss occurs through the pedicel (kernel connection to the cob) of the kernel through the cob tissue. Post-maturity grain moisture loss occurs primarily by evaporative loss from the kernel itself. Research many years ago established that post-maturity moisture loss through the kernel connective tissues (placental tissues) back to the cob is essentially non-existent (Kiesselbach and Walker, 1952; Crane et al., 1959). As those tissues cease to function (associated with the onset of kernel black layer and physiological maturity), the moisture and nutritional connection between kernel and cob is essentially broken.

Related References

Cavalieri, A.J. and O.S. Smith. 1985. Grain Filling and Field Drying of a Set of Maize Hybrids Released From 1930 to 1982. Crop Sci. 25:856-860.

Crane, P.L., S.R. Miles, and J.E. Newman. 1959. Factors Associated With Varietal Differences in Rate of Field Drying in Corn. Agron. J. 51:318-320.

Hicks, D.R. 2004. The Corn Crop – Frost and Maturity. Minnesota Crop News, Univ of Minnesota Extension. [online]. http://www.extension.umn.edu/cropenews/2004/04MNCN28.htm [URL accessed Sep 2011].

Kiesselbach, T. A. and Elda R. Walker. 1952. Structure of Certain Specialized Tissue in the Kernel of Corn. Am J Bot 39:561-69.

Nielsen, R.L. (Bob). 2008. Grain Fill Stages in Corn. Corny News Network, Purdue Univ. [online] http://www.kingcorn.org/news/timeless/GrainFill.html [URL accessed Sep 2011].

Nielsen, R.L. (Bob). 2011. Interpreting Corn Hybrid Maturity Ratings. Corny News Network, Purdue Univ. [online] http://www.kingcorn.org/news/timeless/HybridMaturity.html [URL accessed Sep 2011].

Troyer, A.F. and W.B. Ambrose. 1971. Plant Characteristics Affecting Field Drying Rate of Ear Corn. Crop Sci. 11:529-531.

![]()