It has been my observation that many livestock producers that once used tower silos have transitioned to using plastic tubes for fermenting forages. Employees at the Purdue University Animal Sciences Research and Education Center were harvesting alfalfa this week. This provided an opportunity to use several photographs I had archived and took during the recent harvest to highlight “Best Management Practices” for making bagged chopped silage.

1) When cutting the crop, use a mower-conditioner so it crimps the stem every third or fourth inch up and down the stem without bruising leaves.

2) Swaths can be merged together to form a windrow that meets the capacity of the forage chopper used. In this picture, a wheel rake is used to do the merging. Don’t rake so aggressively that excessive soil gets in the windrow.

3) Set the theoretical length of cut on the chopper near 3/8 inch for forage grasses and legumes. A

video segment of a chopper harvesting alfalfa in the windrow is seen below.

4) Take a chopped representative sample in your hand and squeeze very hard. If moisture oozes from the sample, the windrows need to dry more.

5) Pictured is a small, forced-air oven used to determine if a representative chopped sample is in the target range of 65 percent moisture (35 percent dry matter).

6) The chopped forage is unloaded form the unloading wagon into the small elevator that takes it to the packing component of the bagging implement. See the video clips below.

8) Alfalfa silage made at a correct length of cut, well packed in silage tube bag, and allowed to ferment for a month.

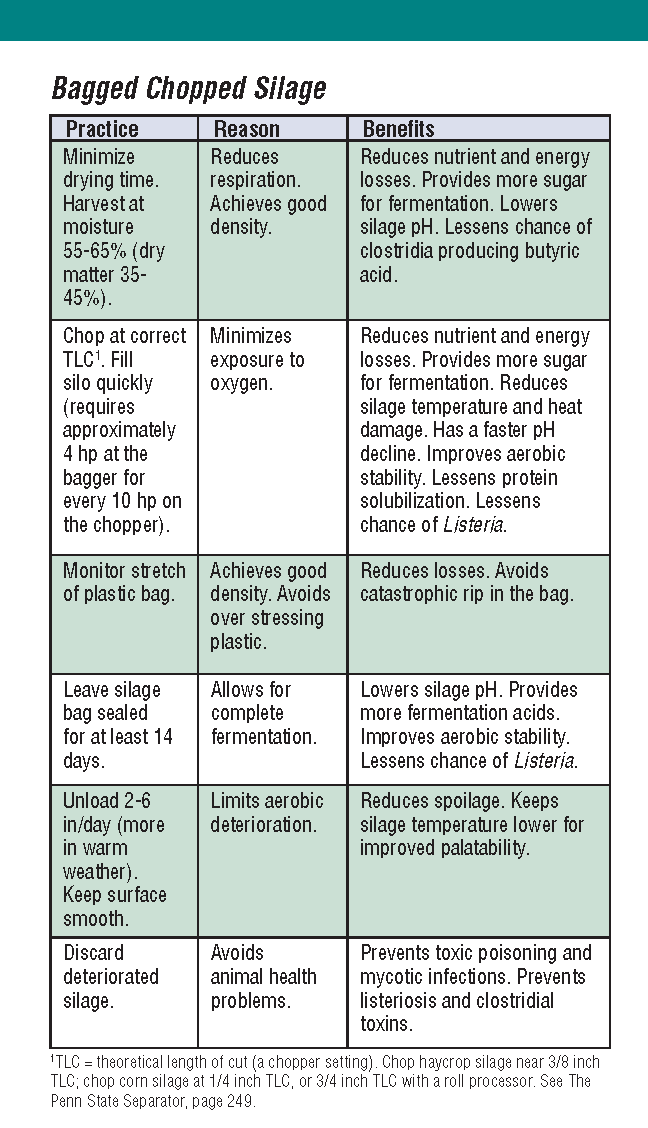

9) Best Management Practices” details for bagged chopped silage from Purdue Forage Field Guide –ID-317. Preference is to have fermentation time of 28 days.

Making quality silage is a process that requires full attention from harvesting a quality crop, chopping at the right length at the correct moisture, and packing it quickly so fermentation can begin immediately.

Photos provide by Keith D. Johnson, Purdue Extension Forage Specialist