Brown Marmorated Stink Bug: Under the Radar for Most – (Christian Krupke and John Obermeyer)

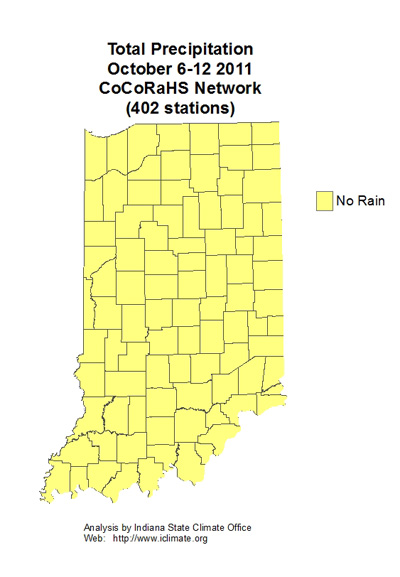

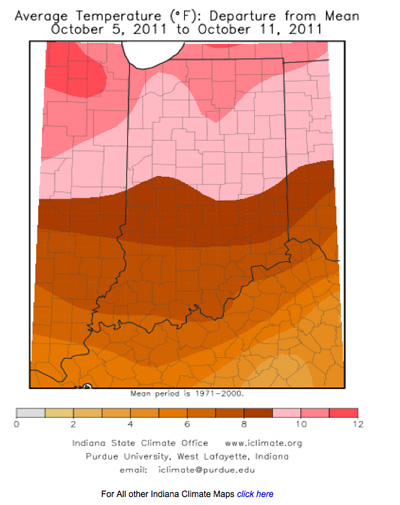

With the string of beautiful fall days have come multiple sightings of the brown marmorated stink bug (BMSB) around Tippecanoe County homes and campus buildings. Interestingly, only reported by staff members of Purdue's Entomology Department. In comparison, one (1) BMSB was found in the Lafayette area last year.

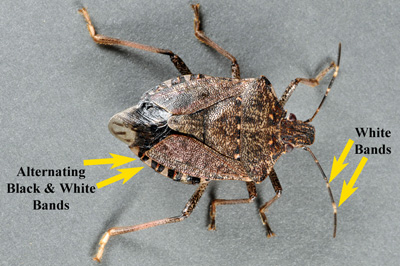

We're certain, that BMSB are active in many areas of the state, especially on warm, sunny days crawling around on sunlit sides of homes and businesses. As one colleague noted, they seem partial to screens on sunrooms. They, like the Asian lady beetle, BMSB are attempting to gain inside access for overwintering. As these beautiful fall days dwindle, please take a look. Should you find BMSB, please let us know. They are quite distinctive from other brownish stink bugs with the 2 light colored patches on their antennae (see picture). Even more helpful is if you can take an in-focus, close-up picture to send to us. Please include location (county and nearest city) and approximate numbers of BMSB.

Key identifying characteristics for the BMSB

BMSB next to pencil point

A few weeks ago, Dr. Tracy Leskey, USDA-ARS, presented to our department a seminar about their experiences with BMSB around her Maryland research facility, as well as, neighboring urban and farming areas. For those attending the Indiana CCA Conference on December 21, she will be presenting this and updated information. Don't miss this presentation! The reason states in the Midwest continue to mention this insect is because this it is the real McCoy when it comes to an invasive insect becoming a serious threat to agricultural crops. Not to mention the tremendous nuisance it is to home/shop owners in the fall. The good news is that it will take another four or more years before it becomes "pest" status in the state, the bad news is that it likely will.

![]()

VIDEO: Considerations for Bean Leaf Beetle Feeding in Late-Maturing Soybean – (Christian Krupke and John Obermeyer)

Admittedly, the following video would have been more timely a few weeks ago. Unfortunately scheduling conflicts didn't allow that to happen. Still, we believe issues addressed in this video will resonate with many pest managers throughout the winter months and into the 2012 growing season. Especially should commodity prices remain high as they are this fall.

The growing conditions this year presented many stresses to our crops, the exact ones probably never to be repeated. The same could be said for insect pests, specifically the bean leaf beetle. This "perfect storm" of fields with very late-maturing soybean and elevated bean leaf beetle populations presented us with ample opportunities to observe their pod feeding abilities. This statewide situation, not seen for over 20 years, caught many pest managers off-guard. Obviously the high commodity prices caused existing, but older, treatment thresholds to be questioned. Overlooked were some timeless IPM precepts, that understanding the targeted pest.

The following video addresses bean leaf beetle identification, biology, and late-season damage to soybean while keeping the marketable portion of the crop foremost in mind. Shown are simple ways to sample for their presence/abundance, an often forgotten step when eyes are concentrating on damage. Too, some very important control considerations for next year are presented.

![]()

Adjuvant Used With Herbicides: Factors to Consider – (Thomas N. Jordan, Bill Johnson, and Glenn Nice)

The terminology for herbicidal additives is confusing. It is often assumed that any material that lowers the surface tension of water in the spray mixture or increases the wettability of the spray solution on plant leaf surfaces is an adequate adjuvant. Since the exact role and function of agricultural adjuvants are not fully understood, the various terms that are used to describe spray adjuvants are often erroneously assumed to be synonymous.

The following discussion is intended to describe the different types of adjuvants that are used with herbicides and explain their role in increasing herbicide efficacy.

Adjuvants are materials that facilitate the activity of herbicides or that facilitate or modify characteristics of herbicide formulations or spray solutions.

Adjuvants are used in herbicidal spray solutions as:

- wetting agents,

- penetrants,

- spreaders,

- co-solvents,

- deposit builders (stickers), and

- stabilizing agents

- drift control agents

These types of adjuvants include:

- anti-foam agents

- buffering agents

- compatibility agents

- liquid fertilizer-herbicide mixtures

Surfactants are materials that facilitate and accentuate the emulsifying, dispersing, spreading, wetting, or other surface modifying properties of liquids.

Wetting agents are compounds that, when added to a spray solution, cause it to cover plant surfaces more thoroughly.

Adjuvants are either included in herbicide formulations as part of the total product, or are sold as an additive to be mixed with herbicide products in a spray tank. Adjuvants can be classified according to their type of action, and the choice of an adjuvant should be based on the specific need to facilitate the herbicide being applied.

There are three basic types of adjuvants used with herbicides:

- Activator adjuvants which include surfactants, wetting agents, penetrants, and oils

- Spray modifier agents which include stickers, film formers, spreaders, spreader-stickers, deposit builders, thickening agents, and foams.

- Utility modifiers which include emulsifiers, dispersants, stabilizing agents, coupling agents, Co solvents, compatibility agents, buffering agents, and anti-foam agents

Spray modifier agents and utility modifier adjuvants, are usually found as part of the herbicide formulation, and thus, are added to the herbicide product by the manufacturer. Activator agents are the best known class of adjuvants because they are normally purchased separately by the user and added to the herbicidal solution in the spray tank. However, there may be a need, at times, to add an adjuvant from any of the three classes to a spray solution to achieve a desired result.

Most of the commonly used postemergence herbicides will show increased activity when an activator agent is added to the spray mixture. The manufacturer of the herbicide will specify on the product label the specific type of adjuvant to add, as well as the concentration at which the adjuvant should be added in order to maximize the efficacy of the herbicide.

When an adjuvant is required in a herbicidal spray mixture, keep in mind the purpose for adding the adjuvant, and use the type of adjuvant that meets the required need.

If spray drift onto sensitive areas is a problem, buy a product to help control drift, not one which increases penetration of the herbicide into the plant foliage. If foaming in the spray tank is a problem, a product which will lower foaming activity should be considered.

Other than adding an adjuvant to decrease spray drift risk or prevent excessive foaming of the spray solution, on-farm adjuvants should primarily be used in accordance with the product label instructions to increase wetting and penetration of foliar applied herbicides. Thus, an activator is the most common adjuvant used on-farm.

Surfactants

Confusion frequently occurs concerning the proper selection and use of surfactants with herbicides. It is wrong to assume that any product that lowers the surface tension of water or increases the wettability of a spray solution can be used as a surfactant.

For example, such products as household soaps and detergents can combine with hard water to form precipitate or scum causing the herbicide to want to fall out of solution, whereas agricultural surfactants keep the herbicide in solution.

There are four basic groups of agricultural surfactants:

- anionic

- cationic

- nonionic

- amphoteric

Nonionic surfactants are the type usually sold for adding to herbicide spray solutions. These surfactants are good dispersing agents, stable in cold water, and have low toxicity to both plants and animals.

Crop Oils

Crop oils and crop oil concentrates, like surfactants, improve coverage of plant surfaces. However, crop oils keep the leaf surface moist longer than water alone or a water and surfactant mixture, allowing more time for the herbicide to penetrate, and thus, increasing the amount of herbicide that will enter the plant.

Crop oil concentrates contain (80 to 87% oil and 13 to 20% emulsifiers/surfactants and are used at rates of about 1 to 2 quarts per acre.

The oil component of crop oil concentrates can be derived from either petroleum oil (Crop Oil Concentrate, COC) or soybean/vegetable oil (Methylated Seed Oil, MSO). One of the most important uses of crop oil concentrates is postemergence herbicides used in corn and soybeans.

Inorganic Salts

In some cases, particularly with acid types of herbicides such as glyphosate, inorganic salts are added to herbicide solutions. While this practice is becoming increasingly popular, there is still relatively little known about the mechanism of action of inorganic salt additives in herbicide sprays. Several popularly used herbicides have included on their label the use of inorganic salts, alone or in combination with surfactants or crop oil concentrates.

Most research indicates that inorganic salts of the monovalent cations of ammonium (NH4+), potassium (K+), or sodium (Na+) salts generally result in the greatest increase in phytotoxicity of water soluble herbicides, with ammonium sulfate being the most popular salt additive. Other salts of divalent and trivalent cations such as calcium (Ca++), zinc (Zn++), and iron (Fe++), for the most part, decrease the activity of commonly used translocated herbicides such as 2,4-D or glyphosate.

Caution should be taken to use the correct inorganic salt that is suggested on the herbicide label, add it to the spray solution at the recommended concentration, and with the suggested surfactant or crop oil that is listed on the herbicide product label.

When purchasing a suitable agricultural adjuvant for herbicide use, consider the following suggestions:

- Purchase an adjuvant that is manufactured and marketed for agricultural use with herbicides.

Do not purchase products made for household use. Many of these detergents are more expensive and less active than agricultural adjuvants. They may be mixed or combined with products that interact with herbicides to reduce the level of weed control. These products can cause foaming or equipment malfunction. - When purchasing a surfactant, buy on the basis of percent active ingredient. Most herbicide labels call for the use of a surfactant with 75% or greater active ingredient. Read the label carefully to determine the active ingredients listed on the surfactant label.

Do not consider isopropyl (isopropanol) and other alcohols or water as active ingredients. Some products list these solvents as part of the active ingredient or as functioning agents. Most spray adjuvants will clearly show on the label, active ingredients, inactive ingredients, and principal functioning agents as a percentage of the total. - Be wary of claims such as, "even though this adjuvant may cost much more, it can be used at lower concentrations than other adjuvants on the market." Many adjuvants have had limited field testing. Little evidence exists to prove that a particular adjuvant is so effective that greatly reducing its concentration over other suitable adjuvants will result in equal or better weed control or reduce product cost.

- Purchase agricultural adjuvants to improve herbicide coverage and penetration into plant foliage. Ignore claims such as "this product has certain properties which will keep the spray equipment clean," or "this adjuvant will increase water penetration into the soil," or "it will increase root penetration or nutrient uptake."

There are no "miracle" adjuvants. Most activator adjuvants are good products and will increase the performance of foliar applied herbicides when used at the recommended rate suggested on the herbicide label. No adjuvant used in a herbicide spray solution can justify a greatly increased price per unit, and none is so effective that the use rates can be lowered below those recommended on the herbicide label.

Soil applied herbicides do not need additional adjuvants. Maximum weed control for soil applied herbicides can best be obtained by applying the proper use rate.

References

- Adjuvants for Herbicides. 1982. Published by the Weed Science Society of America, Champaign, IL.

- Jordan, T.N. 1979. Adjuvants. Crops and Soils Magazine. Nov. 1979, pp. 9-12.

- Wills, G. D. and C. G. McWhorter. 1957. Effects of Salt Additives on Activity and Movement of Glyphosate and MSMA in Purple Nutsedge, Mississippi Agr. and For. Exp. Stn. Tech. Bul. 140. 8 pp.

![]()

Waterhemp – an Emerging Weed Problem in Indiana – (Bill Johnson an Glenn Nice)

Waterhemp has been a significant weed issue in both corn and soybean production in the central and western cornbelt for the last 10-20 years. Waterhemp has been present in Indiana field surveys for at least the last 10 years; however, recent control issues with glyphosate is moving this weed up on the radar of concern for Indiana growers.

This publication first will provide an overview of the biological characteristics that make waterhemp difficult to manage in agronomic crops. Second, it will provide management strategies to help growers better manage this weed and slow the selection of glyphosate-resistant biotypes.

Identification

Waterhemp is a member of the pigweed (or Amaranth) family, which includes other pigweed species commonly found in Indiana including redroot pigweed, smooth pigweed, and occasionally Palmer amaranth. Distinguishing the different pigweed species from one another is challenging, especially in the seedling stages.

Identifying Characteristics

• First true leaves are generally longer than other pigweeds (Figure 1).

• Seedlings are hairless with waxy- or glossy-looking leaves.

• Waterhemp and Palmer amaranth stems are hairless, whereas other pigweeds have hairy stems.

Waterhemp seedling

Smooth pigweed seedling

Figures 1.

As waterhemp matures, it becomes easier to distinguish from the other pigweeds. Waterhemp can range from 4 inches to 12 feet tall, but generally grows to about 4 or 5 feet in most agronomic settings. Mature plant leaves are elongated and often appear waxy or glossy. Stem and leaf color tend to be shades of green, but within a population, some plants often have distinctly red stems or petioles.

Waterhemp is dioecious, meaning that the male and female flowers are on separate pants. The simplest way to distinguish between male and female plants is to rub the mature flowers between your fingers an look for the shiny, black seeds found only on female plants. Redroot and smooth pigweeds are monoecious (that is, the same plant has both male and female flowers). Redroot and smooth pigweeds have denser, more compact seedheads than waterhemp (Figure 2).

Waterhemp

Palmer amaranth

Smooth pigweed

Figures 2

Waterhemp plants emerge throughout the growing season, and a higher percentage of plants emerge later in the season than most other summer annual weeds. Waterhemp plants compensate for small seed size by having higher relative growth rates than most weeds. They can grow almost 1 inch per day during the growing season. Later-emerging waterhemp usually does not affect crop yields; however, seed from uncontrolled plants can contribute a significant amount of seed to the soil seedbank. Waterhemp plants may produce over one million seeds per plant. Such seed production is much greater than with most other weeds. One study found that waterhemp produced more than 1.5 times more seed than other pigweed species of the same size.

Because waterhemp is dioecious, two plants always mix genes when the plant reproduces. This increases a given population's genetic diversity and increases the potential for spreading herbicide resistance and other traits that favor survival in agronomic systems. Pollen movement can transfer herbicide resistance traits across long distances, allowing resistance to quickly jump fences and beyond. Currently, waterhemp populations resistant to ALS-inhibitors, triazines, diphenylethers (PPO-inhibitors), and glyphosate (roundup) have been identified.

ALS-inhibiting herbicides (Pursuit®, Accent®, and many others) were introduced in the mid-1980s and widely used in corn and soybean. After only a few years of use, ALS-resistant waterhemp biotypes were reported throughout the Midwest. This problem grew to such an extent that these herbicides are considered obsolete for waterhemp control.

Prior to the introduction of Roundup Ready® soybean, the primary alternative to ALS-inhibiting herbicides for postemergence waterhemp control in soybean were PPO-inhibiting herbicides (Reflex®, Ultra Blazer®, Cobra®, and others). At present, PPO-resistant waterhemp populations are limited but have been found in several states. Glyphosate-resistant waterhemp populations have been identified in Indiana, Illinois, and several other states.

Control in Corn

Most preplant/preemergence corn herbicides provide effective control or suppression of waterhemp, especially when mixed with atrazine. A follow-up postemergence treatment may be necessary in dense populations or if rainfall promotes emergence later in the season. Postemergence treatments containing atrazine, 2,4-D, dicamba, Status, Callisto, Laudis, Corvus, Impact, and glyphosate (glyphosate-resistant corn) if the waterhemp population is not resistant to glyphosate are effective. Ignite plus atrazine (Liberty Link corn) will control small waterhemp.

Control in Soybean

For best results, start with a preplant or preemergence herbicide that contains sulfentrazone (Authority), flumioxazin (Valor), metoloachlor (Dual). Preemergence herbicides will greatly reduce the waterhemp population, and provide more flexibility in the postemergence application window. A postemergence treatment will usually be required to control late-emerging plants. Effective postemergence treatments include Ultra Blazer, Cobra, Reflex, Flexstar, and Ignite (Liberty Link soybeans), which should be applied when waterhemp plants are less than 4 inches tall. Glyphosate with Warrant or Outlook (Roundup Ready soybean) can be effective where the waterhemp population is not resistant to glyphosate and provide residual control.

![]()

Post Harvest Update and Recertification Workshop - (Linda Mason)

The Post Harvest Update and Recertification Workshop will be held December 5, 2011 at the Beck Agricultural Center, Purdue Agronomy Center for Research and Education, 4540 U.S. 52 W., West Lafayette, IN 47906.

Pre-register and save money $95.00 by Dec. 1 and on-site is $110.00. Registration is limited. The schedule of the day:

8:30 AM Registration, Coffee & Donuts

9 AM - 12 PM Sessions Begin

12 - 12:30 PM Catered Lunch Provided

1 - 4 PM Sessions Contiue

4 PM Complete Certification Forms

CCH's have been applied for. Watch for more detail on our Post Harvest and Grain Quality Website: <http://extension.entm.purdue.edu/grainlab/>.

![]()