Pest & Crop Newsletter, Entomology Extension, Purdue University

- You Can Dig It, Rootworms and Damage

- Soybean Aphid Update

- Prepare Grain Bins for Wheat Harvest

- Black Light Trap Catch Report

You Can Dig It, Rootworms and Damage- (John Obermeyer Christian Krupke, and Larry Bledsoe)

- High-risk fields should be evaluated for rootworms and damage.

- Insecticide efficacy on early-April planted corn is suspect.

- Larval sampling procedures are outlined.

- Rescue treatment guidelines are given below.

Exposed roots revealed larval damage.

Rootworm larvae have begun hatching and seeking corn roots for over two weeks in northern counties and three or more weeks in southern counties. Immediately after hatching the larvae are very small and live mostly within the roots. As they increase in size, so does their damage. They wll feed both inside and outside the roots, causing tunneling and pruning. Rootworm beetles last season were very high in areas, and there is potential for high egg loads in both corn and soybean fields. It would be wise to sample roots of plants in high-risk fields, especially where insecticide efficacy is in question.

You may begin sampling at any time, the larvae will be large enough to spot with the naked eye. To sample for rootworms, use a shovel and lift out the root mass and surrounding soil and place on a dark surface (black plastic garbage bags work well). Carefully break up the clods and sort through the soil. Look for 1/4 to 1/2 inch long, slender, creamy-white larvae with brownish-black heads and “tails”.

The high-tech tools necessary for a rootworm dig.

Once the soil has been separated from the root mass, inspect it for root scarring and pruning. You may find the larvae under the leaf collars that are close to nodal roots; tear these leaves away to check. You may also observe the rootworms sticking out of roots. Repeat this process with several plants representing different areas of a field. An average of two or more larvae per plant represents a rootworm population that signals the need for a rescue cultivation application.

Insecticides applied after planting should be directed toward the base of plants. It is also important to throw soil up around plants to incorporate the insecticide and promote the establishment of brace roots. A good brace root system will help prevent plant lodging and reduce losses due to rootworm feeding. If a no-till field has an economic population of larvae, placing the insecticide on top of the ground will normally not be effective. The only exceptions might be if the soil insecticide is watered in through irrigation or rainfall (ideally a half inch or more). Two liquid soil insecticides, Furadan 4F and Lorsban 4E, are labeled for post-directed applications. If one decides to mix the insecticide with a liquid nitrogen source for a sidedress application, compatibility checks should be made. Broadcasting the insecticide will greatly diminish

rootworm efficacy.

Varioius rootworm stages on penny.

![]()

Soybean Aphid Update - (Christian Krupke, John Obermeyer, and Larry Bledsoe)

Larry Wickert, Wickert Consulting in northern Indiana, found the first soybean aphid in soybean for this year on June 6 in a sentinel plot located in Pulaski County that he is monitoring for soybean rust and aphids, (see http://www.sbrusa.net/ for other soybean aphid monitoring sites and counts). Since that time, a few sightings of very low aphid numbers (less than 5 aphids/20 plants) have been received in Indiana and surrounding states. The biggest surprise was that Frankie Lam, SW Indiana IPM Specialist, spotted some aphids in his sentinel plot in Knox County. Obviously, it is very early in the season and too early to predict soybean aphid activity for the next coming months, but it is worth noting that they have begun the move to soybean, their summer host. Stay tuned.

![]()

Prepare Grain Bins for Wheat Harvest- (Linda Mason)

- Stored grain insect infestations usually begin from poor sanitation.

- Procedures are given to prevent infestations.

- Now is the time to carry through these procedures.

The 2006 wheat harvest will soon be here. Preparing bins for storage now goes a long way toward preventing insect infestations during the summer. Several species of insects may infest grain in storage. The principal insects that cause damage are the adult and larval stages of beetles, and the larval stage of moths. Damage by these insects includes reducing grain weight and nutritional value; causing contamination (alive or dead); odor, mold, and heat damage problems that reduce the quality of the grain.

Newly harvested wheat may become infested with insects when it comes in contact with previously infested grain in combines, truck beds, wagons, other grain-handling equipment, augers, bucket lifts, grain dumps, or grain already in the bin. Insects may also crawl or fly into grain bins from nearby accumulations of old contaminated grain, livestock feeds, bags, litter, or any other cereal products.

Insect infestations can be prevented with good management practices. Now that many grain bins are empty, the following guidelines should be used before the 2006 grain is placed in bins:

- Brush, sweep out and/or vacuum the combine, truck beds, transport wagons, grain dumps, augers, and elevator buckets to remove insect-infested grain and debris.

- In empty bins, thoroughly sweep or brush down walls, ceilings, ledges, rafters, braces, and handling equipment and remove debris from bins.

- Inside cleaned bins, spray wall surfaces, ledges, braces, rafters, and floors with an approved insecticide, Storcide II¨ (chlorpyrifos-methyl (the active ingredient in Reldan - stored grain insecticide) and deltamethrin), Tempo¨ (cyfluthrin), Diacon II¨ (methoprene) or various diatomaceous earth (D.E.) products) creating a perimeter barrier. Outside, complete this barrier by treating the bases and walls up to 15 feet high, plus the soil around the bins. Storcide II must be sprayed in a downward spray only, and if treating the inside of structure, it can only be applied from the outside.

- Remove all debris from fans, exhausts, and aeration ducts (also from beneath slotted floors, when possible).

- Remove all debris from the storage site and dispose of it properly according to area, state, and/or federal guidelines (this debris usually contains insect eggs, larvae, pupae, and/or adults, ready to infest the newly harvested grain).

- Remove all vegetation growing within ten feet of the bins (preferably the whole storage area). Then spray the cleaned area around bins with a residual herbicide to remove all undesirable weedy plants.

- Repair and seal all damaged areas to the grain storage structure. This is not only to prevent insect migration into the bin, but also to prevent water leakage, which leads to mold growth.

- Do not store newly harvested grain on old grain already in storage.

- Whenever fans are not operated, they should be covered and sealed. This reduces the opportunity for insects and vertebrates to enter the bin through the aeration system.

When grain is placed in bin you may treat with an approved insecticide such as Storcide II (not Storcide I) which has CODEX MRL (maximum residue limits) tolerances, so labeled crops protected with Storcide II may be shipped to international markets and any of the D.E. products.

![]()

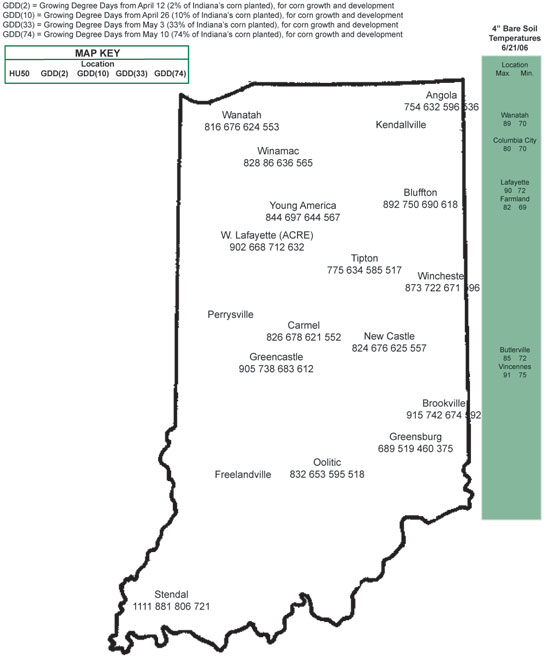

Click for Table.

Black Light Catch Report.

![]()

Glyphosate Rate for the Second Postemergence Application – (Bill Johnson and Glenn Nice)

A fairly substantial number of soybean fields will require sequential or followup treatments of glyphosate to control weeds which were not controlled with the first postemergence application or have emerged since the first application. Important points to consider when deciding what rate of glyphosate to use in the sequential treatment are:

- the size of the weeds that will be treated with the sequential treatment

- the weather conditions we will experience when the treatments are made

- the influence of stalk boring insects on glyphosate activity on large giant ragweed, common ragweed, and lambsquarter plants.

These factors will have a direct influence on the efficacy of glyphosate. The labels of most of the glyphosate products for Roundup Ready soybeans indicate that a total of 2.25 lbs. of glyphosate acid/A can be applied during the growing season (emergence until the end of flowering or R2) and up to 1.5 lbs. of glyphosate acid/A can be applied in a single application. This equates the following product rates for commonly used glyphosate products:

Product |

Lbs. of glyphosate acid /A |

Product rate/A |

Roundup Original Max or Weather Max |

0.75 1.125 1.5 |

22 oz. 33 oz. 44 oz. |

Touchdown Total |

0.75 1.125 1.5 |

24 36 48 |

Other formulations with 3 lbs. of glyphosate acid/gallon |

0.75 1.125 1.5 |

32 48 64 |

The labels of most products indicate that weeds taller than 8 inches should be treated with at least 1.125 lbs. of glyphosate acid/A. This would equate to 33 oz./A of the Roundup Original Max or WeatherMax, 36 oz./A of Touchdown Total, or 48 oz./A of the formulations with 3 lbs. of acid/gallon. You can use up to 1.5 lbs. of acid/A if the amount used for the first application did not exceed 0.75 lb. acid/A.

As mentioned earlier, factors such as hot, dry weather resulting in drought-stressed weeds, big weeds in general or big weeds that contain stalk boring insects can result in poor performance of glyphosate. Under these situations our recommendations would be to use at least 1.125 lbs. of acid/A in the 2nd postemergence or respray treatment.

So, when making the decision on what rate to use for the followup treatment, utilization of the proper rate can result in better performance and less temptation for the 3rd spray trip across the field that has become more common in the last couple of years. Keep in mind that these really late applications are off-label (if they are after the R2 growth stage) and by that time of the growing season, the weeds have already exerted their competitive effect and no yield benefit is likely to occur from the late application.

![]()

It’s Postemergence Season – Do You Know How Big Your Weeds Are? - (Mark Loux and Jeff Stachler – The Ohio State University)

Pest&Crop Readers – Our colleagues at The Ohio State University put together a nice comprehensive article on several issues related to postemergence glyphosate use in soybean and allowed us to run their article in our newsletter.

Every year it seems that even though crop planting can be spread over several weeks or more, the postemergence season happens all at once. Although we usually succeed in making timely postemergence herbicide applications in our research plots, we struggle to stay ahead of the weeds, and many growers and custom applicators face the same challenge. This article offers guidance on maximizing glyphosate effectiveness and preserving maximum yield of Roundup Ready soybeans. The following suggestions are based on research at OSU and other universities, and also on information provided by herbicide manufacturers where appropriate.

In fields where residual herbicides have not been applied, weed control and Roundup Ready soybean yield is maximized when two postemergence (POST) glyphosate applications are used. Make the first application when weeds are no more than 4 to 8 inches tall, and the second approximately three weeks later. This strategy avoids yield loss from early-season weed competition, improves control of weeds that glyphosate is occasionally not completely effective on, and controls late-emerging weeds. It is extremely difficult to accomplish all of this with one POST application, except in fields with low weed populations and no giant ragweed. Those growers who deliberately delay the first POST glyphosate application until just before soybean canopy closure are allowing weeds to compete with soybeans for too long, and consequently, soybean yield is not maximized.

Something to think about for next year – if you find yourself in the position of often applying glyphosate to large weeds, make the decision to use residual herbicides next spring. Early-season weed control from residual herbicides will keep weeds from getting too large, too early, and create a wider window for postemergence applications, so that soybean yield is not reduced due to late POST applications.

Adjust glyphosate rates for weed size. General guidelines for glyphosate rates with regard to weed size (most labels are similar): 4 to 8 inches – 0.75 lb ae/A; 8 to 18 inches – 1.1 lbs ae/A; larger than 18 inches – 1.5 lbs. However, our research shows that more consistent control of many giant ragweed and lambsquarters populations would most likely be achieved by using a rate of 1.1 to 1.5 lbs ae/A in the first POST application, which should be made when lambsquarters is less than 6 inches tall and giant ragweed is no more than 8 to 12 inches tall. A second application is often necessary to ensure the consistent control of these weeds. Using the a rate of at least 1.1 lb ae/A in the first POST application is a more effective strategy than using 0.75 lbs, especially where the population’s sensitivity to glyphosate appears to be declining. In soybeans fields that were not treated with a preplant burndown, use a rate of 1.5 lbs ae/A. The maximum amount of glyphosate that can be applied to Roundup Ready soybeans (total of all POST applications) is 2.25 lbs ae/A.

There are many soybean herbicides that could be mixed with glyphosate in POST treatments. However, our research shows that just increasing the glyphosate rate may be the most effective strategy to improve control in problem situations, along with making a second POST glyphosate application. Some herbicides antagonize the activity of glyphosate, and others add little or nothing to control while increasing the soybean injury. We are not suggesting that use of only glyphosate is an effective strategy in Roundup Ready crops, because this approach is likely to hasten the onset of glyphosate resistance. What we are suggesting is that money spent on herbicides other than glyphosate in Roundup Ready soybeans is best spent on residual herbicides that are applied prior to soybean emergence. One exception is the addition of FirstRate or chlorimuron to glyphosate to improve POST control of glyphosate-resistant marestail, but this will not improve control of populations with resistance to glyphosate and ALS inhibitors.

One of the consequences of allowing weeds to grow to a large size prior to glyphosate application is that it promotes infestation of the plants by stalk-boring insects, which may reduce herbicide effectiveness. University research has shown that the best prevention for this is to apply herbicide when weeds are small, less than about 6 inches tall. This is a more effective strategy than just increasing glyphosate rate, which may not overcome the negative effect of the stalk borers on herbicide activity.

Research at OSU and other universities has shown that the activity of glyphosate is affected by the time of day of application. We conducted a two-year study on this, making glyphosate applications at three-hour intervals from 6 am to midnight. Glyphosate was effective when applied between 9 am and 6 pm, but activity was always reduced at 6 am and midnight, and usually at 9 pm as well. All weed species present in the study except lambsquarters exhibited this effect, and control of ragweed was especially sensitive to time of day. Control of giant ragweed was reduced by 50% or more when applied in the early morning or late evening. Increasing the glyphosate rate did not overcome the effect of time of day. We saw this effect with other herbicides as well. So – what’s our recommendation with regard to time of day? Those of you who are taking advantage of light bars or similar equipment to apply at night or early morning are at risk of poor weed control. Our research suggests that: 1) at this time of the year, we should be applying between the hours of about 8 am and 7 pm to ensure herbicide effectiveness, and 2) using drift-reducing nozzles or adjuvants that allow us to spray at these times is a better strategy to deal with wind than applying at night.

However, don’t overdo drift reduction measures. Simultaneous use of the most effective drift-reducing nozzles and drift-reducing agents can result in too few droplets of large size, which is not ideal for herbicide effectiveness.

A comment on other adjuvants that can be used in POST treatments – don’t mess up the glyphosate’s activity with a bunch of stuff that is not contributing anything. For example, our research shows that it is possible to get a slight increase in glyphosate effectiveness by adding some surfactant (most likely in higher spray volumes which result in lower surfactant concentration). However, most glyphosate products already contain surfactant, and increasing the glyphosate product rate in problem situations results in increased rates of glyphosate and surfactant. It has become fairly standard to add ammonium sulfate (AMS) or an ammonium sulfate substitute product to glyphosate treatments, which serves the purpose of negating the effect of hard water on glyphosate activity and improving control of certain weeds such as velvetleaf. We are not sure that AMS helps for control of small annual weeds at this time of the year when weather is conducive for herbicide activity, but it may help for control of the large weeds that many growers seem to like to spray. AMS can burn soybean leaves in hot weather. This burn can be minimized by using lower rates of AMS – 8.5 lbs per 100 gallons instead of 17 lbs. While the AMS substitute products may be more convenient than adding spray-grade AMS, it can be difficult to assess how effective they are compared to true AMS. The AMS rate is too low in some of these products. Resist the sales pitch on acidifiers and other products that claim to improve glyphosate effectiveness.

Applying glyphosate with manganese has the potential to reduce glyphosate activity. Be sure to use full rates of AMS (preferably the spray grade formulation, not AMS replacements) and only chelated forms of manganese. Add the AMS to the spray tank first, followed by the manganese, followed by the glyphosate. Large weeds (greater than 12 inches) are likely to survive when tank-mixing the manganese with glyphosate, especially velvetleaf. When tank-mixing the two, use glyphosate at 1.1 to 1.5 lbs ae/A to minimize the loss in control due to the manganese.

Glyphosate activity is maximized in low spray volumes – 10 gpa or lower – which should be fine for most small annual weeds. However, spray coverage is an issue when glyphosate is applied to large weeds. Spray volumes of 15 to 20 gpa may provide more effective coverage on large weeds or dense populations. Also – the spray boom should be high enough to ensure that even the taller parts of plants receive spray.

In an effort to have an edge in the marketing battle between glyphosate products, which are usually similar in activity, the rainfree interval has been reduced to as little as 30 minutes on some product labels. Our greenhouse research with lambsquarters indicates that a rainfree interval of 4 hours may be more appropriate.

In fields planted with Roundup Ready corn in 2005, any volunteer corn showing up will also be resistant to glyphosate. This can also occur if your corn field was adjacent to a neighbor’s Roundup Ready corn field due to pollen movement. When applied with just crop oil concentrate, any of the postemergence grass herbicides (sethoxydim is the weakest) for soybeans will control volunteer Roundup Ready corn. When mixed with glyphosate, use only Assure II or Select Max to ensure effective control.

Many perennial species are only now at their optimal size for maximum long-term glyphosate activity. We noticed common pokeweed beginning to show flower buds for the first time last week. For maximum perennial control with glyphosate, apply when the weeds are in the bud to early flowering stage. The most effective glyphosate rate is between 1.1 and 1.5 lb ae/A. A second application is needed for maximum control of many perennial species. Since perennial weed species are usually taller than annual weed species at the time of application, be sure the boom height is set properly to maximize perennial weed control.

![]()

Strip Tillage Corn Impressive Thus Far in 2006 - (Tony J. Vyn)

Despite all the concerns for poor plant establishment and variable growth in corn fields this past spring in Indiana, strip-till corn has been impressive relative to other tillage systems. We have observed higher plant populations as well as much taller corn plants in strip tillage versus conventional tillage (based on fall chisel plowing and spring cultivation) and no-till. The most dramatic growth and establishment advantages for strip tillage were observed for strip-till corn planted on May 10 (Figures 1 and 2), just before the 10 consecutive days of rain and cool temperatures that resulted in the need to replant many corn fields or wetter sections of fields in many parts of Northern Indiana. Our observations this spring prompted a few questions that I will attempt to answer below.

Figure 1. No-till (left of flag) versus strip-tillage (right of flag) effects on corn growth 1 month after planting for corn after soybean on Sebawa Loam soil near Wanatah, IN. (June 10, 2006)

Why would strip-till corn appear to be better than corn in both conventional-till and no-till systems this year? Possible reasons include the following:

1. Strip tillage means adopting a controlled traffic system (at least temporarily). There is never (or should never be) any wheel traffic on the loosened row zones between strip tillage and planting. This reduction in soil

compaction means one less stress for corn seedlings to have to deal with. Corn seedlings suffer substantially more from compounded stresses than from individual stresses associated with wet, cool, compacted and (or) low fertility environments in the soil.

2. Strip tillage results in warmer conditions in the row zone compared to no-till. The relative soil temperature advantage at seed depth depends on the degree of soil loosening that persisted from the original strip tillage operation, and the extent to which the berm height advantage persists after planting. However, if row cleaners on the planter resulted in a seed-row furrow after strip tillage, soil conditions at seed depth can actually be cooler than that in other tillage systems.

3. Strip tillage results in drier conditions in the row zone, and superior macro-pore continuity for drainage under saturated soil conditions than that left after recent secondary tillage operations in conventional tillage. Strip-till also has less surface residue cover than no-till in the immediate row area, and that means faster evaporation of water from the soil surface in the row zone. Ridge-till corn has also been very impressive compared to moldboard and chisel plow systems this year, and a large part of that can be attributed to the ridges being dryer than the between-row zones during May’s 10-day rain period.

Figure 2. No-till (left of flag) versus strip-tillage (right of flag) effects on corn growth 1 month after planting for corn after corn on Sebawa Loam soil near Wanatah, IN. (June 10, 2006)

4. Strip tillage may have been accompanied with banded fertilizer application instead of the traditional broadcast fertilizer application of P and (or) K fertilizers in no-till and conventional tillage programs. Banding of N and P fertilizers has promoted more vigorous early corn growth this spring than has been noticed in some previous years. Therefore, and especially in situations of no starter application with the corn planter, deep-banded (but not too deep) P applications with strip tillage may have further improved the growth rates of strip-till corn relative to other tillage systems.

Does an early height advantage necessarily mean higher grain yields with strip tillage corn than for other systems? No. Relative plant heights by themselves are a poor indicator of final yields for tillage systems (see representative results in Table 1). Higher mean plant heights in May or June may indicate something about earlier physiological maturity in fall, but final yields are more dependent on the timing and severity of subsequent growing season stresses than they are dependent on early height advantages. In addition, plant height variability itself may be more important to final yield than relative height means in response to tillage. Indeed, the whole aspect of the uniformity of individual corn plant growth and development within a row (canopy) from V-4 to the R-1 stage may have a greater influence on final yields than a slower mean rate of corn growth by itself.

Does the accuracy of corn planting on strip-tilled zones (berms) in spring matter? Yes, at least in terms of initial corn growth rates. In several fields we have seen dramatically shorter corn plants when the actual row position is to the side of the original strip-tilled berm. It seems that the accuracy of planting following strip tillage mattered even more in 2006 than in previous years. In some fields the corn growth advantage for precise versus erratic planting after strip tillage may be due to soil physical conditions alone (e.g., improved soil warmth in the strip-tilled zone), but in other fields it may also be a response to corn plant proximity to deep-banded fertilizers.

Figure 3. Strip-till corn response to RTK row-positioning at planting (right of flag) versus row displacement of 6-7" from the center of the strip-tilled zone (left of the flag) on silty clay loam soil near West Lafayette, IN. (June 13, 2006)

How can we achieve more precise row positions following strip tillage? It isn’t simple to plant precisely in the center of the strip-tilled zones when planting visually (and especially at night, or following weather situations that have flattened the original berms or repositioned the between-row residue cover back over the berms). I acknowledge that failure to plant more accurately may have prevented us from achieving more instances of positive yield results from strip tillage versus other tillage systems in our own tillage research over the past 20 years. However, we don’t know what the grain yield consequences are of various departures from the center of strip-tilled zones. In a new experiment for 2006, we are directly testing the consequences of precision auto-guidance (via RTK, or real-time kinematic) for planting on the center of strip-tilled zones versus intentional displacements of 6-7” or non-intentional displacements resulting from planting by our best visual judgment (i.e., without RTK guidance). RTK planting seemed to provide some growth advantages for corn planted on April 11 (Figure 3).

Overall, most strip-tilled corn fields look promising in 2006. But appearances alone are not enough to justify a management change by farmers. Strip tillage adoption usually has many other management factors associated with it (e.g., considerations involving deep-band versus broadcast

Figure 3. Strip-till corn response to RTK row-positioning at planting (right of flag) versus row displacement of 6-7” from the center of the strip-tilled zone (left of flag) on silty clay loam soil near West Lafayette, IN. (June 13, 2006)

fertilizer application, requirement for starter fertilizer with the planter, and how well the system would work for corn after corn versus corn after soybean). We will try to keep you informed with as many research results as we can gather with the very limited funding available. Nevertheless, the grain yield results from this year’s strip tillage plots and corn fields should be particularly interesting.

![]()

Bug Scout

Ol' Obe heard one of the neighbors say rootworms were so thick you could hear them chomping-- but he doesn't trust his hearing!

![]()

Weeds the Center of Attention at Annual Field Event – (Steve Leer, Agricultural Communications)

Weeds can show up unannounced in almost every crop and farm field. At an annual Purdue University field day visitors can learn how to keep those surprise visits to a minimum.

Weed Research Field Day takes place from 8:30 a.m. to 3:30 p.m. June 27 at Purdue farms near Lafayette and West Lafayette, Ind. The event is free and open to the public.

Herbicide manufacturers, dealers, consultants, farmers and Extension educators are encouraged to attend. A maximum of five Continuing Credit Hours are available for 1A classification commercial applicators.

The field day emphasizes corn, soybean and popcorn weed management programs, said Tom Bauman, Purdue Extension weed specialist and the event coordinator.

“Participants will have the opportunity to learn from and interact with Purdue weed- science professionals,” Bauman said. “This season proves to be a challenge because of the two and a half weeks of very cold and wet conditions we experienced.” Field day participants are not the only ones benefiting from the event. Purdue researchers benefit, as well, Bauman said.“The field day allows us to interact and gain knowledge about different issues facing professionals in the field,” he said. “This allows us to tailor our recommendations to the state to meet industry needs.”

This year’s field day is divided into a morning session at the Agronomy Center for Research and Education (ACRE) and an afternoon session at Throckmorton-Purdue Agricultural Center. ACRE is located about six miles west of Purdue’s West Lafayette campus, off U.S. 52. Throckmorton is located south of Lafayette along U.S. 231.

During the morning session participants will have an opportunity to look at industry programs for corn, soybeans and popcorn and compare them to new herbicides, as well as evaluate the effects of varying chemical formulas on herbicide performance. Graduate students will be available to discuss their research field plots.

The afternoon session, beginning at 1:30 p.m., consists of touring weed plots at Throckmorton. Participants will view trials on the influence of various soil-applied herbicides on early season weeds in corn, giant ragweed management in soybeans and interaction of glyphosate and various tank mix products.

Participants will need to provide their own transportation from ACRE to Throckmorton, and maps will be provided at the morning session.

To register for the field day, contact Amy Deitrich at (765) 494-9871. Box lunches and refreshments will be provided for registered participants.

For more information, contact Bauman at (765) 494-4625. The field day is sponsored by Purdue’s Department of Botany and Plant Pathology.

![]()

OSU Weed Science Field Day

The OSU Weed Science field research tour will be held at the OARDC Western Agricultural Research Station on Thursday, July 6. The tour, which is self-directed in nature, starts at 9 am and runs until noon. OARDC Western Agricultural Station is north of South Charleston on State Route 41, approximately 5 miles south of Interstate 70. There is a cost of $5 per person for the tour.

![]()