Pest & Crop Newsletter

|

||||||||||||||||||||||||||||||||||||||||||||||||

Rootworm Control and Damage, it's a Numbers Thing– (John Obermeyer and Larry Bledsoe)

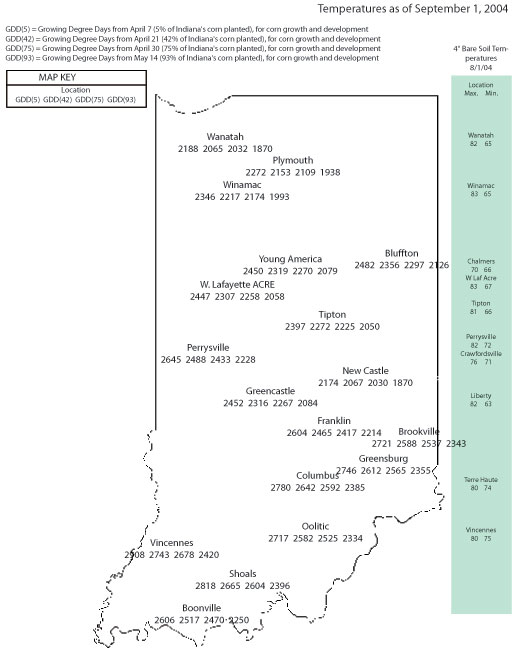

Rootworm larval pressure and product performance varies within the field and from field to field. We, and other universities, evaluate efficacy of rootworm control products following very late-planted corn or "trap-crops." Trap-crops attempt to provide uniform larval feeding pressure the following season by attracting massive numbers of rootworm beetles that feed-on the pollen/silks leading to mating and egg-laying within that field. We have been doing this for years to test experimental and labeled rootworm products. However, rootworms often don't cooperate in providing us the severe, and certainly not uniform, pressure desired. That's why we conduct these tests at multiple locations in Indiana and randomly replicate treatments within the plots. Producers often unwillingly create similar scenarios by replanting drowned out areas, allowing weed escapes in areas of a field, or not monitoring for variant western corn rootworm beetles in soybean. When producers purchase and apply rootworm materials they expect CONTROL. Still it is not unusual for producers to notice areas of cornfields that have been lodged while out combining. These lodged areas may be a result of serious root feeding from a concentration of eggs laid the previous season. The numbers of eggs, or "egg-load," deposited in a given area or whole field is the most important of all variables determining the following year's risk to rootworm feeding. High egg-loads, coupled with optimal soil conditions for larval survival in the spring, will likely cause significant rootworm damage to corn causing plant lodging and possibly death. This will occur even when control products are used properly (time of application, placement, etc.) and at the labeled rate. In other words, control products can be "overwhelmed" with rootworm numbers. Comparing the 2004 efficacy data on the following page, you will see we got serious damage at the Pinney Purdue Agricultural Center (PinPAC) at Wanatah in northwestern Indiana. The PinPAC site was moderately dry throughout the summer, but had well timed rains that resulted in excellent growth of the corn. Although, the results at the Northeast Purdue Agricultural Center (NEPAC) at Columbia City represent average damage from rootworm larvae for that region, this damage was highly variable. That site received an atypical amount of rain (about 20 inches) from May through July with more than 7 inches in 72 hours in mid June and probably accounts for the increased variability and overall low rootworm damage. Two other Indiana test sites were abandoned because of early-season saturated soils that resulted in near total mortality of rootworm larvae. The biggest surprise when comparing 2004 data is the reduced efficacy of YieldGard® Rootworm at PinPAC. Granted this is only one site in Indiana that we are reporting, but it is the first time that we have measured YGRW trait performance that is much lower than anticipated. Apparently rootworm Bt corn is also showing some surprisingly poor ratings in University of Illinois plots where rootworm pressure was excessive. No one at this time knows for certain why this new technology for rootworm control has shown a "kink in the armor." You can be certain that many rumors concerning Bt-corn performance will spread this fall and coming winter. University and industry entomologists will be closely studying this situation. It simply may be a matter of the rootworm larval numbers overwhelming the Bt-toxin expressed in the roots. We know that larvae must feed on the roots to ingest the Bt and then either die or become dramatically delayed in growth and development. Enough "sick" larvae may still do significant damage when larval numbers are extremely high. Unlike Bt corn for above-ground lepidopteron insects (e.g., corn borer) that has given near 100% control, YieldGard Rootworm expresses a lower dose of the toxin in the roots which allows for a small percentage of surviving larvae. To keep this in perspective, other than this one test plot, we are not aware of any suspected poor performance of rootworm Bt corn in Indiana at this time. In the coming days of harvest, farmer's observations made through their combine windshields and by their yield monitors will add to our understanding of how this product protected corn in many environments and how that protection was associated with productivity. Corn rootworm, especially as it pertains to the western corn rootworm variant, and additional product performances will be featured in the November issue of the Pest&Crop.

Grain Bin Clean-Up– (Linda Mason and John Obermeyer)

Storage facilities should be readied for corn that will likely carryover to next spring or summer. Preparing bins for storage now goes a long way toward preventing insect infestations. Several species of insects may infest grain in storage. The principal insects that cause damage are the adult and larval stages of beetles, and the larval stage of moths. Damage by these insects includes reducing grain weight and nutritional value, and by causing contamination (as live or dead insects), odor, mold, and heat damage that reduce the quality of grain. Newly harvested corn may become infested with insects when it comes in contact with previously infested grain in combines, truck beds, wagons, other grain-handling equipment, augers, bucket lifts, grain dumps, or grain already in the bin. Insects may also crawl or fly into grain bins from nearby accumulations of old contaminated grain, livestock feeds, bags, litter, any other cereal products, or rodent burrows. Insect infestations can be prevented by employing good management practices. Now that many grain bins are empty, the following guidelines should be used before the 2004-grain is placed in bins:

No Reports of Hessian Fly Damage in 2004– (Sue Cambron)

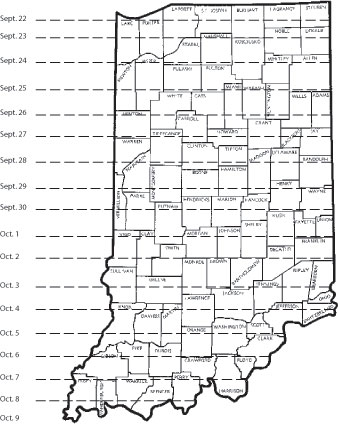

The Hessian fly is present in wheat-growing areas throughout Indiana and often survives, although in lower numbers, in wheat stubble or grasses during the summer. No fly damage was reported in Indiana in 2004, and less than 1/10th percent infestation was found in the uniform Hessian fly nursery from southern Indiana. However, there is potential for rapid increase of fly populations as a result of weather conditions or cropping practices that favor survival of eggs and young larvae in the fall. Much of the fall fly population can be avoided by planting after the fly-free date. This is key to avoiding subsequent infestation by the spring brood. Additionally, it has been shown that following the fly-free date will help reduce wheat disease problems and reduce winter kill from excessive growth. Crop rotation, where wheat following wheat is avoided, also is one of the key management strategies for reducing Hessian fly problems. The Hessian fly passes the summer in the stubble of the current wheat crop. Plowing the stubble results in the destruction of the pest. Volunteer wheat germinates and begins growing just in time for the fall emergence of the Hessian fly. These plants are readily infested resulting in a rapid build-up of the population. Removal of volunteer wheat before the emergence of the fall brood greatly reduces the insect reservoir for a spring infestation. The wet fall in 2003 contributed to much of the wheat crop being planted late and therefore most was planted well past the fly-free dates for the state. If weather conditions this fall are mild there could still be an infestation of flies that survive on surrounding grasses, so following the fly-free dates for planting is always recommended (see Indiana's fly-free dates below).

Click for Table.

|

||||||||||||||||||||||||||||||||||||||||||||||||

Preharvest Assessment of Indiana Corn Crop– (Charles Woloshuk and Burt Bluhm)

On August 25, we traveled to southwestern Indiana. We detoured off both sides of Hwy 41 starting around Sullivan in the morning and finishing the day at Cynthiana. As we cruised the back roads, we stopped at cornfields and looked for ear rot diseases. Overall, this year appears to be one of the best corn crops we have seen. The ears are big, with kernels to the tips. We saw less than normal evidence of insect damage on the ears. As a result, we found very few fields with ear rots. We could find Diplodia ear rot in many fields north of Vincennes. However, the incidence was low - a level that we would consider normal for this area. In the worst fields, we found Diplodia ear rot on 1 in 30 ears that we examined. The ears without this disease were beautiful. From Vincennes southward, we found nothing but beautiful corn ears. We recorded only one ear with Diplodia ear rot. On our way back to campus, we traveled through Hendricks County. Unlike the corn in southwest Indiana, which is at or near maturity, the corn in Hendricks County is still green. In the fields we examined, the ears we perfect with no diseases or insect damage. We received a call from an elevator near the border with Kentucky, where they reported seeing higher than normal cob rot damaged grain (Diplodia). This is coincidental with a report out of the University of Kentucky extension that warned of high levels of Dipodia ear rot in Kentucky. One last bit of information comes from our annual corn ear rot and mycotoxin survey. The Indiana Agricultural Statistics Service has sent us corn samples from 14 fields so far. We typically evaluate samples from about 150 fields each year. Three of the 14 fields had an ear with Diplodia ear rot. Diplodia ear rot is enhanced by dry weather prior to silking followed by wet conditions at and just after silking. Hybrids differ in their susceptibility to Diplodia ear rot. Ears are most susceptible to this disease during the first 21 days after silking. When infection occurs within two weeks after silking, husks prematurely become bleached or straw colored, and entire ears are white to grayish or grayish brown, shrunken, and lightweight. Lightweight ears generally stand upright with the inner husks adhering tightly to each other. Black specks (pycnidia) may be scattered on the husks, cobs and sides of kernels. Ears infected later in the growing season generally have a somewhat uniform whitish to grayish mold growth over and between the kernels starting at the base of the ear and progressing towards the tip. Infected kernel tips are discolored. Proper storage at or below 15% moisture prevents further development of Diplodia ear rot. Long-term storage is not recommended because of the damage to kernel integrity and the increased amounts of foreign matter (cob and broken kernels) in the grain. There are no known mycotoxins produced by the Diplodia fungus in the United States, therefore feeding the grain to livestock is possible, keeping in mind that the nutrient value of the grain may have diminished.

|

||||||||||||||||||||||||||||||||||||||||||||||||

Purdue Agronomy Field Day, 14 Sept. - (Bob Nielsen) The 2004 Purdue Agronomy Field Day will be held TUESDAY, September 14 at the Purdue Agronomy Center for Research and Education. Tours will focus on a) genetic technologies for corn insect & weed management, b) crop variety testing and on-farm research, c) grain quality assurance programs, d) yield monitor calibration techniques, and e) auto-steer technologies & high accuracy GPS systems. Field day registration (free) will begin at 8:00 a.m. The first round of tours will be offered at 8:30 a.m. Check out the tour schedule www.agry.purdue.edu/FieldDay/tours.html for specific tour departure times. A new twist to this year’s field day will be the inauguration of the “Kitchen Sink” yield/profit plots. Field day attendees will have the opportunity to evaluate comparisons of corn production practices in side-by-side large plots (12 rows by length of field) and cast their ballots for which will a) yield the most and/or b) be most profitable. More information about the field day can be found at www.agry.purdue.edu/FieldDay/. For other Corny News Network articles, browse through the CNN Archives at www.kingcorn.org/news/index-cnn.html. For other information about corn, take a look at the Corn Growers’ Guidebook at www.kingcorn.org.

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||