USDA-NIFA Extension IPM Grant

Pest & Crop Newsletter, Entomology Extension, Purdue University

An Overview of Corn Ear Rots – (Kiersten Wise) -

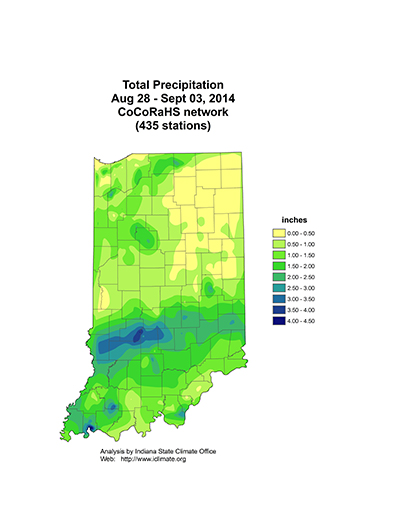

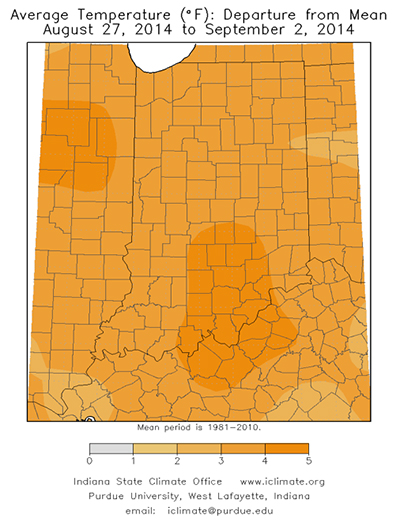

Weather conditions are favorable for several different ear rots of corn in Indiana this year. As harvest begins, it is important to identify fields that may have ear rots to ensure timely harvest and proper storage of moldy grain. Several economically important ear rots may appear in Indiana this year, including Diplodia ear rot, and Gibberella ear rot. A different fungus causes each of these rots, and the environmental conditions at and just after silking influence which ear rot may be problematic in a given year. Additionally, some of these fungi are able to produce mycotoxins as a byproduct of the infection process. Mycotoxins can be toxic to humans and livestock, and are carefully regulated in food and feed. Proper identification of ear rots is key for managing affected grain.

Diplodia Ear Rot

Diplodia ear rot is caused by the fungus Stenocarpella maydis, and is very common in cornfields across the Corn Belt. This fungus survives in residue and infects plants approximately two weeks after pollination. Humid weather and rains prior to and after pollination will favor disease development. Diplodia ear rot is identified by white fungal growth on the cob, often forming a mat of fungus across the ear (Figure 1). Infected kernels may also be brown-gray in appearance. Small, black fungal structures called pycnidia may form on the kernels or the cob. The fungus is reported to produce a mycotoxin called diplodiatoxin in South America and South Africa, however, no reports of toxic effects of grain on livestock or humans due to Diplodia ear rot have been reported in the United States. Grain dockage may still occur, however, due to moldy grain.

Figure 1. The fungus that causes Diplodia ear rot produces a white fungal mat on the cob.

Gibberella Ear Rot

Gibberella ear rot, caused by the fungus Gibberella zeae, is common during cool, rainy years, like 2009 and 2014. The fungus infects during early silking and pollination, and is favored by cooler temperatures than the previously described ear rots. This fungus produces a fungal mat on the ear, similar to Diplodia ear rot, but often with a pink or reddish color to the mold (Figure 2). Gibberella zeae produces the mycotoxin deoxynivalenol (DON), commonly referred to as vomitoxin. This mycotoxin can be extremely harmful to swine, and is carefully regulated according to the FDA action levels defined in Table 2.

Figure 2. A pink mold on the ear is a sign of the fungus that causes Gibberella ear rot (picture courtesy Charles Woloshuk).

| Table 2. U.S. FDA action levels for DON contaminated corn. Source: FDA Regulatory Guidance for Toxins and Contaminants. <http://www.ngfa.org/files/misc/Guidance_for_Toxins> | |

| Animal | Maximum DON level allowed |

| Ruminating beef and feed lot cattle (more than 4 months old) | 10 ppm (not to exceed 50 percent of diet with finished feed = 5 ppm) |

| Poultry | 10 ppm (not to exceed 50 percent of diet with finished feed = 5 ppm) |

| All other Animals | 5 ppm (not to exceed 40 percent of diet) |

Ear Rot Management

Preventative management of ear rots is critical, and can be accomplished by selecting less susceptible hybrids and reducing the amount of corn residue that can serve as a source for the fungus to overwinter. This is accomplished through crop rotation and tillage. In-season management of ear rots is limited at this point, with few fungicides and anti-fungal products available for specific ear rots. Efficacy data for these fungicides are limited.

Farmers should scout fields prior to harvest and determine the level of incidence of any ear rot in the field. If ear rots are observed in a field, affected areas should be harvested early and grain segregated to avoid mycotoxin contamination of non-infected grain. Silage and grain harvested with suspected ear rots should be dried to below 15% moisture. If grain or silage (with kernels present) is kept above this moisture content, mycotoxin can continue to accumulate in grain. All grain contaminated by any ear rot fungus should be stored separately from good grain, and if stored long term, stored below 13% moisture to prevent further growth of fungi.

Click here to see the 2014 Corn Earworm Trap Report

![]()

A Few Things to Do Before Corn Harvest – (Bob Nielsen) -

I am still hopeful that most of Indiana’s 2014 corn crop will physiologically mature in September and that the bulk of the harvest will occur in its usual October timeframe. As the 2014 corn crop heads down the “home stretch” toward physiological maturity and harvest, here are a few items you may want to add to your “honey do” list.

Walk fields and look for evidence of ear rot development.

Dr. Kiersten Wise, Purdue plant pathologist, tells me that conditions back around pollination were favorable (cool and moist) for infection of the ear silks by some of the ear rot fungal organisms. Most of us remember the challenges (some say nightmares) brought on by ear rots back in the fall of 2009. Two in particular to look for are Gibberella (pinkish-red mold generally near tip of ear) and Diplodia (whitish-gray mold generally near base of ear). Severely affected fields should be targeted for early harvest, rapid drying of harvested grain to 15% moisture or less, and segregation from healthy grain. For more information, browse the linked articles.

Walk fields and look for evidence of cannibalized or hollowed out lower stalks and, possibly, stalk rot development.

This year’s high yield potential is being partially driven by large kernel numbers per ear. These high kernel numbers per ear create, in and of themselves, a photosynthetic stress on the plants because of the demand for photosynthate by the developing kernels. Normally, this photosynthate is generated “on the fly” by active photosynthesis in a healthy crop. If, however, other stress (foliar disease, nitrogen deficiency, drought, hail, late-season flooding, etc) limits the photosynthetic rate of the crop, the plants sometimes resort to cannibalizing the carbohydrates stored in the lower stalk tissue and remobilizing them to the developing grain. This remobilization physically weakens the lower stalk and makes it more vulnerable to infection by root- and stalk-rot fungal organisms.

Scout by a) pushing on the stalks to see whether they break or crumple, b) bending over and pinching the lower stalk internodes to see whether they collapse easily, or c) splitting open the lower stalks with a knife (don’t cut yourself) and looking for visible evidence of stalk rots (discolored, shredded appearance). Target severely affected fields for early harvest to minimize the risk of significant stalk breakage / lodging prior to harvest.

Take a Sunday afternoon stroll through nearby corn hybrid demonstration trials.

Choosing hybrids for next year can be very challenging for many reasons. During this “down time” prior to harvest, make the effort to visit those signed corn hybrid trials in the neighborhood. Make notes on those visual hybrid characteristics that are important for your decision-making process. Some of the characteristics you may want to consider include:

Ear height above the ground. Hybrids with high ear placement can be more prone to stalk lodging because of the high center of gravity the high ears represent.

Many trials at the moment are far enough away from physiological maturity that you can still evaluate relative resistance to foliar diseases like gray leaf spot or Northern corn leaf blight. This year in some areas of the state, hybrid variability relative to these two important diseases is vivid.

Relative stalk health among hybrids. Re-read the previous “honey do” item regarding stalk health assessment.

Ear size in terms of row number and kernels per row, plus kernel set success on the ears (pollination success, kernel survival). Also kernel size as the hybrids near maturity.

Husk coverage on the ear. Some folks favor husk coverage way beyond the tip of the ear that may offer some protection against earworms, others favor shorter husk leaves that may allow for faster drydown.

Once kernel black layer occurs (physiological maturity), there is some advantage for ears that shift from upright to a declined position (droopy if you prefer). Droopy ears tend to shed rainfall better than upright ears during the important field drydown period and so may drydown slightly faster than upright ears.

Search through the stack of unread user manuals on the shelf and locate the one for the yield monitor in your combine.

Put the user manual on top of the filing cabinet next to your desk. Make room for it, if necessary, by clearing off the old issues of farm magazines, farm newspapers, Sports Illustrated Swimsuit editions, and farm auction flyers.

Then go to your refrigerator for two bottles of your favorite beverage, open each one, and set them down on your desk next to the filing cabinet.

Next, pick up the user manual, open it, and read through the table of contents or perhaps in the index in the back and look for the section that describes the procedure for calibrating the yield monitor.

Drink the first bottle of your favorite beverage and careful begin reading through the yield monitor calibration procedure in the user manual.

If necessary, drink the second bottle of your favorite beverage and continue reading through the yield monitor calibration procedure.

Carefully and clearly highlight each of the calibration steps and, if necessary, transcribe carefully to individual Post-It™ notes or use the impossibly small keypad on your smartphone and type them into your favorite Notes app on your smartphone for future reference.

If necessary, go to your refrigerator for a third bottle of your favorite beverage and drink all of it.

Calibrate your yield monitor.

Once you have fully digested the seemingly complicated steps of the yield monitor calibration procedure, take the time and effort to actually calibrate your yield monitor before you begin grain harvest. While you may not yet be comfortable climbing on to the “Big Data” bandwagon, you nevertheless should be proactive in doing what you can to maximize the accuracy and quality of the yield data generated every year in your farming operation.

The essence of yield monitor calibration is to “train” the “black box” of the monitor to accurately interpret the electrical signals coming from the impact sensor or the electric eye as they relate to grain flow rates and, therefore, accurately estimate grain yield from the estimated grain flow rates. Sound complicated? Not really.

The yield monitor simply needs to experience the range of grain flow rates that it is likely to encounter in your fields in order to accurately estimate grain yields that correspond to those grain flow rates. If you only use high yield calibration “loads”, then the monitor has no idea what to do when it encounters grain flow rates in areas of the field that are yielding significantly lower. That is why many user manuals suggest using calibration “loads” harvested at a) different speeds or b) different numbers of corn rows through the head in order to artificially create that range of grain flow rates (and, thus, yields) during calibration.

You can supplement these artificially derived grain flow rates with calibration harvest passes through your field that clearly represent differently yielding areas in the field. In our field-scale nitrogen rate trials, we use the range of N rate treatments as our calibration “loads” because they effectively “capture” the range of grain yields that the yield monitor will likely encounter.

Calibration requires a) patience, b) access to an accurate grain moisture meter, c) access to accurate weigh scales, and d) those Post-It™ notes or smartphone Notes referenced in the previous “honey do” item. It sometimes helps if you are also anal-retentive about accuracy.

Recognize that many yield monitors should be frequently checked for accuracy as harvest moves along into the fall and re-calibrated when necessary. One of the biggest factors that influences the accuracy of yield monitors over time is the change in grain moisture one field to another. That’s why you also need access to an accurate grain moisture meter.

Related Reading

Nielsen, RL (Bob). 2010. Yield Monitor Calibration: Garbage In, Garbage Out. Corny News Network, Purdue Extension. <http://www.kingcorn.org/news/timeless/YldMonCalibr.html> [URL accessed Aug 2014].

Nielsen, RL (Bob). 2013. Stress During Grain Fill: A Harbinger of Stalk Health Problems. Corny News Network, Purdue Extension. <http://www.kingcorn.org/news/timeless/StalkHealth.html> [URL accessed Aug 2014].

Shaner, G. E. and D. H. Scott. 1998. Stalk Rots of Corn. Purdue Extension Publ. #BP-59. <https://www.extension.purdue.edu/extmedia/BP/BP-59.pm65.pdf> [URL accessed Aug 2004].

Woloshuk, Charles and Kiersten Wise. 2009. Diseases of Corn: Diplodia Ear Rot. Purdue Extension Publ. #BP-75-W. <https://www.extension.purdue.edu/extmedia/BP/BP-75-W.pdf> [URL accessed Aug 2014].

Woloshuk, Charles and Kiersten Wise. 2010. Diseases of Corn: Gibberella Ear Rot. Purdue Extension Publ. #BP-77-W. <https://www.extension.purdue.edu/extmedia/BP/BP-77-W.pdf> [URL accessed Aug 2014].

![]()