Pest & Crop Newsletter, Entomology Extension, Purdue University

- Nematode Updates - Corn Nematodes

- Cutworms May be Feeding Now, Bugt Not Black Cutworm

- Don't Forget the Alfalfa Weevil Scouting

- Black Cutworm Adult Pheromone Trap Report

Nematode Updates - Corn Nematodes - (Jamal Faghihi, Betsy Bower, Christian Krupke, and Virginia Ferris)

- Forecasted weather conditions may favor needle nematode populations.

- Stunted corn with stubby roots on sandy soil may be symptoms of needle nematode damage.

- Sampling for corn nematodes is best done about a month after planting.

- Nematode seed treatments for corn need further evaluations.

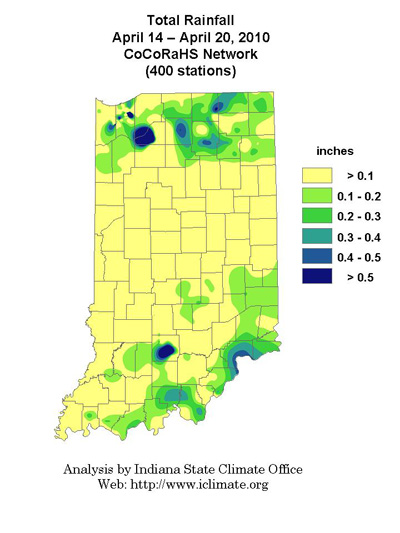

If we had written an article about corn nematodes last week, when it was still warm and the soil dry, we might have predicted that certain nematodes in corn might not be a problem this year. This week, however, the temperature has gone down and rain is in forecast, so we may need to change our predictions.

Needle nematode damage on crown roots

Needle nematode damage to corn

Needle nematodes, the most yield-limiting nematodes in Indiana’s corn, need a cool and wet spring to increase in population to economically damaging levels. Other nematodes, like lance and lesion nematodes, do not require those conditions to be a problem. Unseasonably warm temperatures this spring have activated all corn nematodes. They are desperately looking for food and they are eagerly awaiting germination of corn plants. So if conditions turn to be cool and wet, needle nematodes could be a problem on sandy soils as they were last year. If you have had problems on corn before, and weather conditions change in the nematodes’ favor, you might consider sampling for nematodes. In this case, you may wish to send the entire root system with adjacent soil to the Nematology Laboratory, address below, at Purdue University for analysis. Samples must be kept cool and moist. The best time to sample for needle nematodes is 4-6 weeks after planting.

Under high nematode pressure, roots do not develop normally. The roots are truncated and resemble root inhibitor (dinitroaniline) herbicide injury. Similar symptoms are also present when lance nematodes are causing a problem. Lesion nematodes, however, will not cause the described root symptoms. But, symptoms for most plant parasitic nematodes are usually in patches and do not follow a uniform pattern in the field.

We used to believe that needle nematodes disappear when soil temperature rises above 85°F. Our understanding changed last year, when we were able to find needle nematodes until the end of the season, when we found these nematodes on crabgrass. Last year was a very unusual year weather-wise. We had high moisture and low temperatures most of the season.

In short, be alert to environmental conditions that are favorable for needle nematodes and enable them to cause yield loss. These conditions are specific to needle nematodes and do not apply to lance and lesion nematodes. The latter species feed throughout the season and they could be a problem in all types of soils and weather.

Many of you have inquired about the use of seed treatments for nematode control. We have had mixed results in our trials and need additional data to be able to determine their efficacy. We will have field plots under high nematode pressure, and are hopeful that we can provide more informed recommendations by the end of the season.

If you have any questions about corn nematode or any other kind of plant parasitic nematodes, you can contact Jamal Faghihi at 765-494-5901 or send an email to jamal@purdue.edu. Soil samples for nematode analysis can be sent to: Nematology laboratory, Purdue University, Department of Entomology, Smith Hall, 901 W. State Street, West Lafayette, IN 47907-2089. The cost for nematode analysis for each sample remains at $10/sample. However, if we have to incubate the roots to extract internal nematodes an additional $10/sample will be charged. Additional information and sampling form can be found on our Nematology website: <http://extension.entm.purdue.edu/nematology/services.html>.

Cutworms May Be Feeding Now, But Not Black Cutworm - (Christian Krupke, John Obermeyer, and Larry Bledsoe)

- Many species of cutworms feed on corn.

- Black cutworm is the most common and damaging species but is just beginning to arrive in the state.

- The dingy, variegated, and claybacked cutworm species all overwinter as partially grown larvae.

- The dingy and variegated cutworms are mainly leaf feeders, whereas the claybacked will also cut plants.

- Seed treatments aren’t highly effective against these other species, because of their large size when feeding.

Many cutworm species look alike and identification is often confusing. Black cutworm is occasionally an economic threat to corn when moth arrival, egg laying, and crop emergence coincide. As the name suggests, the black cutworm will cut or burrow into plant stems, causing stand losses. Generally, the black cutworm is our most commonly found species damaging the crop, which is why most assume it is the culprit when damage is found.

Black cutworms do not overwinter in the Midwest, which is why we monitor their arrival each spring with pheromone traps. Once they arrive in large numbers (also called “intensive captures”) we begin predicting their development and subsequent damage with heat unit accumulations. Thus far, there has not been an intensive capture recorded in Indiana and there have not been sufficient heat units accumulated this spring for black cutworm to get 1/2 to 3/4 inches long – the size when they begin to cut plants. So, if one is finding cutworm damage on emerged corn at this time, there is another cutworm species to blame…that being one of the dingy, variegated, and/or claybacked cutworms.

Notice the course texture, "bumps," of the black cutworm skin

Close-up of the dingy cutworm skin shows that it is relatively smooth

Claybacked cutworm skin texture is similar to the dingy, mostly smooth (Thanks to Darren Boebel, Pioneer Hybrids for sending larvae from Knox County)

Variegated cutworm have distinct dorsal, yellowish dots on several of the body segmentsy

The dingy, variegated, and claybacked cutworm species all overwinter in Indiana as partially grown larvae. They actively feed on many forage and weedy plants in the fall, where they cease feeding and become dormant under mats of plants (e.g., chickweed) for their winter’s nap. As temperatures begin to increase in the early spring, they resume feeding. When weeds are killed by spring herbicide applications, they move to alternate food sources… if available, this could include the emerging crop. Because these larvae are about ¾ inch in length at this time of year, they aren’t deterred much by the relatively low-rate of insecticidal seed treatments. Therefore, depending on density of worms and the rate of the crop’s growth and development, damage can be quite significant.

The dingy and variegated cutworms are primarily leaf feeders and will rarely cut plants, and if they do, the cutting is above ground level. Because a corn plant up to the 5-leaf stage can withstand severe defoliation without a yield loss (compare it to frost damage), treatment for these cutworms is rarely justified. However, the claybacked cutworm’s damage is a mix of leaf feeding and plant cutting so black cutworm thresholds should be followed. To add to the confusion, other species of cutworms may be encountered feeding on crops as well. The sandhill cutworm, as its name implies, is found on sandy knolls. Sandhill and the glassy cutworms tend to be a perennial threat in specific environments, most producers are quite aware of their destructive abilities.

Identification of these cutworm species is a little tricky and requires a pretty good understanding of morphological characteristics of immature insects, a course taught in Entomology. In short, while using a 10X magnifying lens, carefully analyze the skin texture of the worm. If it is considerably “bumpy,” it is most likely a black cutworm. The other cutworm species have smooth skin. Species identification can be confirmed by sending us live or “pickled” worms. Place the worm in a pill bottle alongside a 5th of Jack Daniels and carefully wrap the bottle for shipping. Please contact us before doing so. Happy Scouting!

![]()

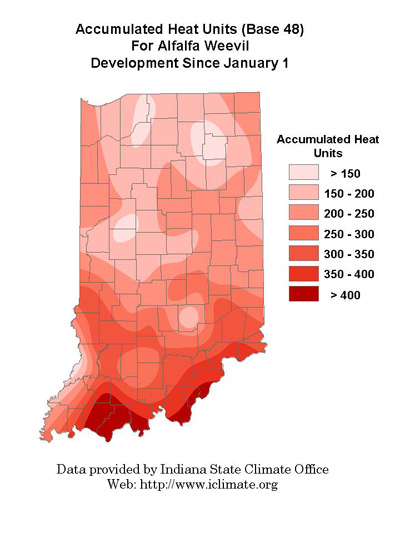

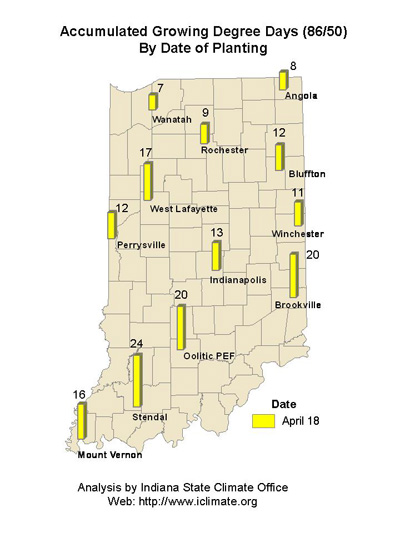

Don’t Forget the Alfalfa Weevil Scouting – (Christian Krupke and John Obermeyer)

This pest is often overlooked during the early spring planting season, especially this year! Producers can manage this pest most effectively by utilizing heat unit accumulations data (base 48°F) to determine when sampling should begin and when an action should be taken, The management guidelines listed below should be used to determine when alfalfa weevil should be controlled in southern Indiana. Refer to the following heat unit map to track weevil development in your area.

Severe alfalfa weevil damage will cause fields to look frosted as you drive by

| Heat Units | % Tip Feeding | Advisory |

|---|---|---|

| 200 | Begin sampling. South facing sandy soils should be monitored earlier. | |

| 300 | 25 | Re-evaluate in 7-10 days using the appropriate HU or treat immediatley with a residual insecticide if 3 or more larvae are noted per stem and % tip feeding is above 50% |

| 400 | 50 | Treat immeiately with a residual insecticide. |

| 500 | 75 | Treat immediately. |

| 600 | 75+ | If cutting delayed more than 5 days, treat immediately. |

| 750 | If harvested or harvesting shortly, return to the field in 4-5 days afer cutting and spray if 1) there is no regrowth and weevil larvae are present OR 2) feeding damage is apparent on 50% of the stubble and weevil larvae are present. |

![]()

Click here to view the Black Cutworm Adult Pheromone Trap Report

Quick Check For Calibration – (Tom Jordan, Bill Johnson, Glenn Nice, and Tom Bauman)

Easy method to keep your Sprayer Accurate:

Most everyone starts the season out by repairing and calibrating their spray equipment. How many recalibrate on a regular basis? In an old survey from Iowa State University, it was reported that only about 40% of those surveyed admitted to checking to see if their equipment was still applying the right amount of liquid sometime later into the growing season. This probably has not changed much over the years; however, with computer equipment now used in herbicide applicators, it is easier to catch calibration errors. Still, this is a quick and easy process that takes only a few minutes of time, a catch bucket that measures ounces, and a stick to scratch out a few numbers in the dirt (pencil and paper works also). There are several ways to initially calibrate spray equipment, but below is a quick way to check that it is still correct after the equipment has been used.

Once the sprayer has been partially filled with water and before the herbicide is added, run the equipment in a neutral gear at the RPM’s you would spray at and catch the output from each nozzle using the simple formula:

Sec. to catch 1 quart = 89,100

(W)X (GPA) X (MPH)

W = width between nozzles in inches

GPA = gallons per acre you want to apply

MPH= miles per hour you are driving

The number 89,000 is a constant that takes into account everything that you need to calibrate in gallons per acre. This formula can be simplified if you round off the 89,100 to 90,000. By changing it to 90,000 you change the constant by only 1%, which is probably the most accurate thing you are going to do in the whole calibration process. The 1% is only for that part of the formula, which means that for the whole process you are changing the results by some few tenths of a percent.

Sec/qt = 90,000

(W) X (GPA) X (MPH)

Say you want to spray 20 GPA from a sprayer with 20 inch spacing between nozzles. Your ground speed is 6 MPH.

Sec/qt = 90,000

(20) X (20) X (6)

Sec/qt = 90,000

2,400

24

Sec/qt = 37.5

You need to catch 1 qt in 37.5 (37 or 38) seconds and you will be calibrated at 20 GPA. One quart equals 32 oz. If you divide the time (37.5 sec.) by 2 then you can catch 1pt (16oz) in 19 seconds and you will still be calibrated at 20 GPA. Check each nozzle for this output and you are calibrated. Try this simple process with your own numbers.

Fungicide Applications for Foliar Wheat Disease Management – (Kiersten Wise)

- 2010 Wheat Fungicide Efficacy Table Available.

- Consider disease presence, variety susceptibility,

and economic factors before deciding on a foliar

fungicide application to wheat.

Wheat is at or approaching Feekes growth stage 7 in most areas in southern Indiana. Wheat in Tippecanoe county is still at Feekes 5 to 6. The amount of time it takes from jointing (Feekes 6) until flag leaf emergence (Feekes 8) depends on temperature. Research conducted by Dr. Greg Shaner found that it takes between 12 and 17 days for wheat to progress from jointing to flag leaf emergence in Indiana. Therefore, if producers are considering fungicide applications at flag leaf emergence through boot stage (Feekes 8-10), now is a good time to review the fungicides available for foliar wheat disease management.

In Indiana, foliar fungicides are commonly applied to manage the Stagonospora /Septoria leaf blotch complex in wheat. This complex produces tan to brown, round to elliptical lesions (Figure 1) on lower leaves initially. Warm nights (over 45°F), and a few days of rainy, cloudy weather can promote infection and disease development. When lesions form on the flag leaf or above, the disease may contribute to yield loss.

Several factors should be considered to determine if a fungicide application is needed, including the susceptibility of the variety planted to disease and the level of fungal disease as wheat reaches Feekes 8-10. When scouting fields, examine the lower leaves of the wheat plant to see if lesions are present, and monitor weather forecasts to determine if conditions will be favorable for disease development. If there are no lesions or very few lesions on lower leaves, and the weather is warm and dry through boot stage, a fungicide application for leaf blotch management may not be necessary. If the weather becomes more favorable for disease and lesions are observed two leaves below the flag leaf, and the variety is susceptible to leaf blotch, a fungicide application may be beneficial. Economic factors such as expected yield and crop price should also be considered.

Fungicides were tested for foliar disease control in a trial in West Lafayette, IN in 2009 (Table 1). In this trial fungicides were applied to a variety susceptible to the foliar leaf blotch complex. Fungicides were applied at full flag leaf expansion through boot stage (Feekes 9 -10).

The cost of a fungicide application can range from $16.00 to $25.00 per acre, depending on the fungicide product, and application method. A break-even response calculated based on an application cost of $20.00/A, and a wheat price of $5.00/bu means that yield must increase by 4 bu/A to pay for the cost of the fungicide application. In the 2009 trial, the break-even threshold of 4 bu/A was reached in 4 of the 6 treatments tested.

There are several fungicides available for use against foliar wheat diseases. The NCERA-184 committee is composed of university wheat pathologists, and each year this group discusses how labeled fungicides products perform against wheat diseases, and post ratings in a wheat fungicide efficacy table. The 2010 version can be accessed at the following website: <http://www.ppdl.purdue.edu/ppdl/wise/NCERA_184_Wheat_fungicide_chart_2010_v2.pdf>. This is an excellent resource for selecting fungicide products to manage foliar wheat diseases, as well as Fusarium head blight, or scab.

Figure 1. Lesions typical of Septoria/Stagonospora leaf blotch of wheat

(Photo Credit: G. Shaner)

| Treatments | Rate (fl. oz./A) | Application Timing (Feekes Growth Stage) | Septoria Leaf Blotch (% on Flag Leaf) 6-9-09 |

Yield (bu/A) | Test Weight (lbs./bu) |

|---|---|---|---|---|---|

| Untreated | 9.3 | 90.1 | 57.7 | ||

| Prosaro | 6.5 | 9 | 3.4 | 95.8 | 58.0 |

| Headline | 6 | 9 | 6.4 | 95.4 | 58.0 |

| Quilt | 14 | 10 | 1.8 | 93.2 | 57.2 |

| Prosaro | 6.5 | 10 | 4.0 | 91.9 | 57.7 |

| Twinline | 7 | 10 | 8.3 | 94.9 | 57.6 |

| Stratego | 10 | 10 | 5.8 | 96.2 | 57.3 |

| LSD (0.05) | 4.3 | NS | 0.6 | ||

| CV (%) | 68.9 | 5.8 | 0.98 |

![]()

Requirements for Uniform Germination and Emergence of Corn – (Bob Nielsen)

Rapid, uniform germination and emergence of corn help set the stage for maximum grain yield at the end of the season. Without such a successful start to the season, the crop is behind the proverbial “eight-ball” right from the beginning. The good news is that there are only four simple requirements for uniform germination and emergence of corn. The bad news is that one or more of the requirements are sometimes absent in one field or another.

Adequate and Uniform Soil Moisture at the Seed Zone. Adequate soil moisture is most simply defined as not too dry and not too wet. Most growers know what “adequate” looks and feels like. Uneven soil moisture in the seed zone can be caused by variable soil characteristics, tillage patterns, unusual weather conditions and uneven seeding depth. Uneven soil moisture throughout the seed zone is the primary cause of uneven emergence, the results of which can easily be yield losses of 8 to 10 percent. Remember that uneven seedbed soil moisture can be described as:

Useful Tip: When seedbed conditions are dry, make sure that your choice of seeding depth ensures uniformly adequate soil moisture for the germination of the seed. Even though a 1.5 to 2 inch seeding depth is a good choice for many conditions, don’t hesitate to increase seeding depth to 2.5 to 3 inches if that is the depth where the uniform soil moisture is located. Planting shallower than 1.5 inches increases the risk of poor or uneven germination during subsequent drying of surface soils.

Fig. 1 Uneven corn emergence in 2006 due to uneven (too wet vs. "just right") seedbed moisture

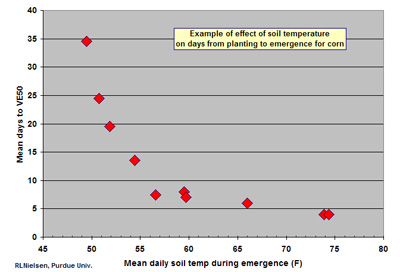

Adequate and Uniform Soil Temperature at the Seed Zone. Corn will germinate and emerge slowly and unevenly when soil temperatures are less than 50F. When soils warm to the mid-50’s or warmer, emergence will occur in seven days or less if soil moisture is adequate. Thermal time from planting to emergence is approximately 115 growing degree days (GDDs) using the modified growing degree formula (Nielsen, 2008) with air temperatures or about 119 GDDs based on soil temperatures.

Uneven soil temperature in the seed zone can be caused by variable soil texture, soil color, soil drainage, surface residue cover in reduced tillage systems and seeding depth control. Temperature variability during germination and emergence is most critical when average soil temperatures are hovering about the critical 50F minimum threshold value.

Useful Tips: Dark-colored soils will typically warm more quickly than light-colored soils. If soils dry differently across the field, the drier areas will typically warm faster than the wet areas. Uneven residue cover (surface trash) in reduced tillage systems causes significantly lower soil temperatures under the heavier cover than under barer spots in the field. Uneven seeding depth exposes deeper planted seeds to slightly cooler seed zones than seeds placed shallower. Consider row-cleaning attachments for the planter to move aside the surface trash during planting and expose the seedbed to sunlight and its warming effects. Consider strip tillage practices in the future to better manage surface trash in a reduced tillage system.

Fig. 2 Example of the effect of soil temperature on the timing of corn emergence

Adequate and Uniform Seed-to-Soil Contact. In order for the kernel to absorb moisture quickly and uniformly, soil must be firmed completely around the kernel. Seed-to-trash contact results from “hair-pinning” of surface trash into the seed furrow during no-till planting when soil and/or trash are too wet for adequate coulter cutting action. Seed-to-clod contact results from planting into cloddy fields created by working soil too wet. Seed-to-rock contact is, needless to say, not good for proper germination either. Seed-to-air contact results from open planter furrows when no-till planting into excessively wet soils. Germination of kernels lying in open planter furrows is dependent.

Useful Tips: Whippers, wipers, movers, fingers, and other similar trash management gadgets for the planter are most beneficial when you are challenged with rocky, cloddy, or trashy surface soil conditions. They help clear the way (literally) for the planter’s double-disc openers to more easily do their job of creating an optimum seed furrow. Other planter attachments that help press the kernels into the seed furrow can improve seed-to-soil contact and seeding depth uniformity when seedbed conditions are otherwise challenging.

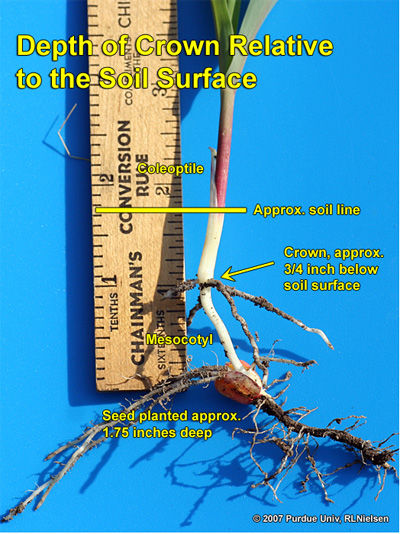

Surface Soil Free From Crust. Severe surface crusting or compaction will restrict emergence of the coleoptile and cause underground leafing or plant death. Severe sidewall compaction can also limit elongation of the mesocotyl and emergence of the coleoptile.

Useful Tip: Avoid excessive tillage prior to planting the crop, especially if significant rainfall is forecast prior to emergence of the crop. Avoid excessive downpressure on the closing wheels of the planter. Avoid planting “on the wet side” that often results

Related References

Carter, Paul, Emerson Nafziger, and Joe Lauer. Uneven Emergence in Corn. North Central Regional Extension Pub. No. 344. [On-Line]. Available at <http://corn.agronomy.wisc.edu/Pubs/UWEX/NCR344.pdf>. [URL accessed April 2010].

Jasa, Paul. 2007. Avoiding Sidewall Compaction at Planting - Don’t Plant Too Shallow. CropWatch Newsletter, Univ. of Nebraska. [On-Line]. Available at <http://tinyurl.com/y56dwly>. [URL accessed April 2010].

Nielsen, RL (Bob). 2008. Heat Unit Concepts Related to Corn Development. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/HeatUnits.htm>. [URL accessed April 2010].

Nielsen, RL (Bob). 2010. The Emergence Process in Corn. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/Emergence.html>. [URL accessed April 2010].

Nielsen, RL (Bob). 2010. Visual Indicators of Germination in Corn. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/GerminationEvents.html>. [URL accessed April 2010].

![]()

The Emergence Process in Corn – (Bob Nielsen)

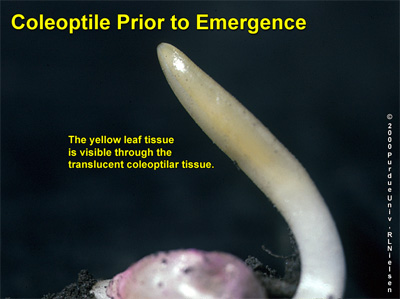

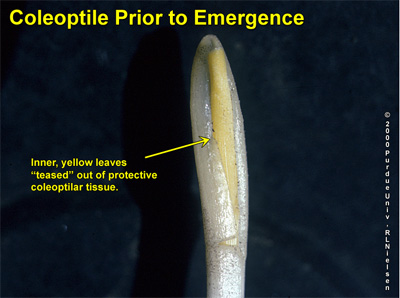

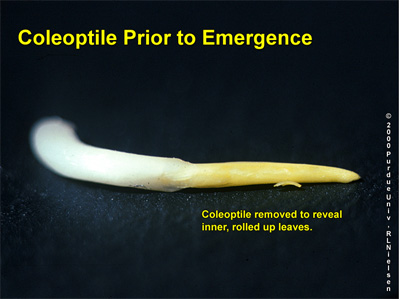

Successful germination alone does not guarantee successful emergence of a corn crop. The coleoptile must reach the soil surface before its internal leaves emerge from the protective tissue of the coleoptile. Growth stage VE refers to emergence of the coleoptile or first leaves through the soil surface (Ritchie et. al., 1993).

As with all of corn growth and development, germination and emergence are dependent on temperature, especially soil temperature. Corn typically requires from 100 to 120 GDD (growing degree days) to emerge. Under warm soil conditions, the calendar time from planting to emergence can be as little as 5 to 7 days. Under cold soil conditions, emergence can easily take up to four weeks.

Elongation of the mesocotyl elevates the coleoptile towards the soil surface. The mesocotyl is the tubular, white, stemlike tissue connecting the seed and the base of the coleoptile. Technically, the mesocotyl is the first internode of the stem.

Useful Tip: Mesocotyls have the physiological capability to lengthen from at least a 6-inch planting depth. Realistically, corn can be planted at least three inches deep (if necessary to reach adequate moisture) and still emerge successfully.

As the coleoptile nears the soil surface, exposure to the red light wavelengths of solar radiation causes a change in the supply of one or more growth hormones from the coleoptile to the mesocotyl tissue and mesocotyl elongation comes to a halt (Vanderhoef & Briggs, 1978). Since the depth at which the emerging seedling senses red light is fairly constant, the resulting depth of the crown (base) of the coleoptile is nearly the same (1/2 to 3/4 inch) for seeding depths of one inch or greater.

Useful Tip: When corn is seeded very shallow (less than about 1/2 inch), the crown of the coleoptile will naturally be closer to the soil surface if not right at the surface. Subsequent development of the nodal root system can be restricted by exposure to high temperatures and dry surface soils.

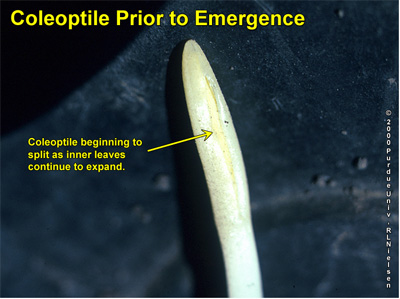

Continued expansion of the leaves inside the coleoptile eventually ruptures the coleoptile tip, allowing the first true leaf to emerge. If mesocotyl elongation has successfully elevated the coleoptile tip to the soil surface, emergence of the first true leaves will also occur successfully above the soil surface.

Troubleshooting Considerations

Several factors can cause the coleoptile to split prematurely, allowing the leaves to emerge underground. Usually, more than one of the following factors are present when this problem occurs, making it difficult to place the blame on any one factor.

Exposure to light at deeper soil depths than usual due to cloddy seedbeds, dry seedbeds, sandy soils, or open slots in no-till.

Injury from certain herbicides, particularly under stressful environmental conditions. Symptoms include corkscrewed coleoptile, swollen mesocotyl and true leaves emerged from side of coleoptile.

Surface crusting, cloddy seedbeds, rocky seedbeds, planter furrow compaction, or otherwise dense surface soil that physically restrict mesocotyl elongation and coleoptile penetration. The pressure of the expanding leaves within the coleoptile eventually ruptures the side of the coleoptile. Symptoms include corkscrewed coleoptile, swollen mesocotyl and true leaves emerged from side of coleoptile. Note the similarity to those symptoms from herbicide injury.

Cold temperature injury, either from exposure to long periods of soil temperatures around 50°F (10°C) or from exposure to wide daily swings (25 to 30 degrees) in soil temperatures. Symptoms include absence of emerged coleoptile, corkscrewed mesocotyl or coleoptile and true leaves emerged from side of coleoptile. Note the similarity to those symptoms from herbicide injury.

Useful Tip: The mesocotyl should remain firm, white and healthy through at least the 6-leaf stage, if not longer. If it is mushy, discolored, or damaged prior to this stage, then it is likely part of the crop problem being investigated.

Related References

Nielsen, RL (Bob). 2008. Heat Unit Concepts Related to Corn Development. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/HeatUnits.html>. [URL accessed April 2010].

Nielsen, RL (Bob). 2009. Corkscrewed Corn Seedlings. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/articles/timeless/Cornscrews.html>. [URL accessed April 2010].

Nielsen, RL (Bob). 2010. Visual Indicators of Germination in Corn. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/GerminationEvents.html>. [URL accessed April 2010].

Nielsen, RL (Bob). 2010. Requirements for Uniform Germination and Emergence of Corn. Corny News Network, Purdue Univ. [On-Line]. Available at <http://www.kingcorn.org/news/timeless/GermEmergReq.html>. [URL accessed April 2010].

Ritchie, S.W., J.J. Hanway, and G.O. Benson. 1993. How a Corn Plant Develops (SP-48). Iowa State Univ. [On-Line]. Available at <http://www.extension.iastate.edu/hancock/info/corn.htm>. [URL accessed April 2010].

Vanderhoef, Larry N., and Winslow R. Briggs. 1978. Red Light-inhibited Mesocotyl Elongation in Maize Seedlings. I. The Auxin Hypothesis. Plant Physiology 61: 534-537.

Closeup of corn coleoptile

Coleoptile beginning to split

Inner leaves 'teased' out of coleoptile

Coleoptile removed to reveal inner leaves

Early "EV" stage

Corn seedling morphology at emergence

Crown depth