Pest & Crop Newsletter, Entomology Extension, Purdue University

2009 Pest&Crop Reader Survey - Only your input can help us improve this publication! We would appreciate you taking a few moments to answer some questions concerning the Pest&Crop Newsletter. The following survey is voluntary and anonymous. All information collected is confidential and no hidden tracking of individual responses is being used. Click here to begin the survey.

Corn Ear Rots Widespread in Indiana – (Kiersten Wise and Charles Woloshuk)

Diplodia and Gibberella ear rot of corn have been observed in many fields in Indiana this year. In fact, the incidence of Gibberella ear rot (Figure 1) has reached levels not seen in Indiana for decades, and there have been several reports of high levels of the mycotoxin DON associated with these infections. Early reports indicate that DON (also known as vomitoxin) levels in corn grain range from 0.2 to 8 ppm, which poses a concern if grain is to be used for livestock feed. Zearalenone is also produced by the Gib ear rot fungus. Zearalenone has estrogenic properties, which lead to infertility, abortion, or other breeding problems. As little as 1 to 5 ppm zearalenone in a feed ration may produce an estrogenic effect in swine.

Figure 1. Gibberella ear rot on corn

The cool, wet weather over the past two weeks have prolonged conditions favorable for ear mold growth. At this point in the season, producers should scout remaining fields of corn and take note of areas and hybrids with ear rot problems. If Gibberella is present and the crop is insured, contact your insurance provider BEFORE harvesting the field to determine if adjustments are needed. Infected fields should be harvested as soon as possible, and grain should be dried to below 15% moisture to prevent further fungal growth. The freezing temperatures that occurred in northern Indiana this weekend will slow fungal growth, however this will not reduce mycotoxin levels in ears infected with Gibberella ear rot. Temperatures near freezing can enhance zearalenone production. Thus, the freezing and thawing weather pattern that we are experiencing throughout Indiana may impact the level of zearalenone in the diseased grain in the field. Infected fields should still be harvested in a timely manner and stored accordingly.

Selecting partially resistant hybrids and rotating fields out of corn will reduce the risk of a re-occurrence of Gibberella and Diplodia ear rots next year.

Please refer to the previous article on Gibberella ear rot for information on where to have grain analyzed for mycotoxin levels, and FDA animal feeding advisory levels for the mycotoxins DON and zearalenone: <http://www.agry.purdue.edu/ext/corn/news/others/2009/Gibberella-1002.pdf>.

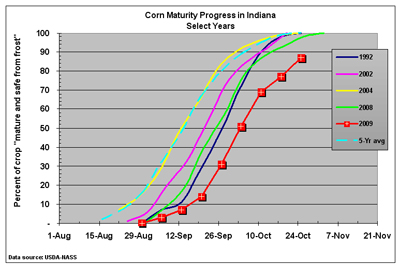

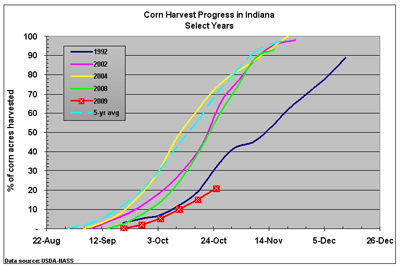

Monday’s report from the USDA National Agricultural Statistics Service (USDA-NASS, 2009) reaffirms that the 2009 Indiana corn crop is continuing its near-record slow pace of development, maturity, and harvest. As of 25 October, 87% of the state’s corn crop had reached maturity (Fig. 1) and 21% of the crop was reported as having been harvested (Fig. 2). These numbers represent progress that is 3 to 4 weeks behind the five-year pace for maturity and harvest.

Indiana farmers have held off harvest of corn because they have concentrated on harvesting the similarly delayed soybean crop and because corn grain moisture has been literally too wet to harvest without incurring mechanical grain damage or wetter than desirable in terms of the expense of grain drying or price dockage at the elevators. Further delays in harvest of both crops have resulted from the frequent periods of rain throughout the state.

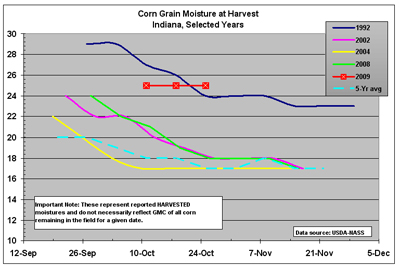

Throughout much of the growing season, the 2009 crop was tracking similarly to the cool 1992 crop (Nielsen, 2009a; Nielsen, 2009b), but has since fallen behind even that very slow crop year (Fig’s 1 & 2). Recent weeks with rainy weather and cool temperatures have simply put the brakes on the drying progress of the grain in standing corn fields around the state. Reported grain moistures at harvest have held steady at 25% grain moisture content for the past three weeks (Fig. 3); in line with those reported in 1992 but much higher than we typically experience in mid- to late October.

Fig. 1. Progress of the 2009 Indiana corn crop in reaching physiological maturity (source: USDA-NASS, as of 10/25)

Fig. 2. Harvest progress of the 2009 Indiana corn crop (source: USDA-NASS, as of 10/25)

Fig. 3. Reported grain moisture content at harvest for the 2009 Indiana corn crop (source: USDA-NASS, as of 10/25)

Even at this late date, some folks seem to be waiting for a miraculous arrival of “Indian summer” to hasten the in-field drying of corn grain so that they can harvest at moistures of 20% or less. Meanwhile, stalk health and grain quality continue to deteriorate due to the processes of weathering and disease.

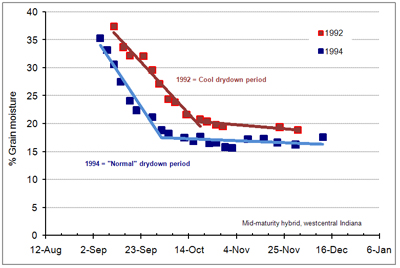

Recognize that grain moisture content typically decreases very, very slowly from late October onward. By late October, one can usually not expect much more than 1/4 to 1/2 percentage point decrease per day with NORMAL temperatures.

The AVERAGE daily temperature statewide for Indiana in October is 53.6°F, then drops to average daily temperatures of only 42.3°F during November (Indiana State Climate Office, 2009). These climatic data explain why the rate of grain moisture loss in the field “drops off like a rock” during October and basically “flat lines” through November (Fig. 4). Factor in this October’s cooler than normal temperatures and it is no surprise why grain moisture has not changed very significantly in recent weeks.

Fig. 4. Example of field drying progress of a mid-maturity corn hybrid in 2 years with different temperature patterns

The bottom line is that we should not expect much more significant grain drying in the field from this point forward unless that miraculous “Indian summer” arrives in the very near future.

Related References

Indiana State Climate Office. 2009. [online] <http://climate.agry.purdue.edu/climate/facts.asp>. [URL accessed Oct 2009].

Nielsen, R.L. (Bob). 2009a. A Tale of Three Cropping Seasons. Corny News Network, Purdue Univ. [online]. <http://www.kingcorn.org/news/articles.09/CropProgress-0803.html>. [URL accessed Oct 2009].

Nielsen, R.L. (Bob). 2009b. Cool Days, Cold Nights, Slow Corn, What’s Next? Corny News Network, Purdue Univ. [online]. <http://www.kingcorn.org/news/articles.09/CropProgress-0901.html>. [URL accessed Oct 2009].

Nielsen, R.L. (Bob). 2009c. Field Drydown of Mature Corn Grain. Corny News Network, Purdue Univ. [online]. <http://www.kingcorn.org/news/timeless/GrainDrying.html>. [URL accessed Oct 2009].

Nielsen, R.L. (Bob). 2009d. Stress During Grain Fill: A Harbinger of Stalk Health Problems. Corny News Network, Purdue Univ. [online]. <http://www.kingcorn.org/news/timeless/StalkHealth.html>. [URL accessed Oct 2009].

USDA-NASS. 2009. Crop Progress. USDA National Agricultural Statistics Service. [online] <http://usda.mannlib.cornell.edu/usda/current/CropProg/CropProg-10-26-2009.pdf>. [URL accessed Oct 2009].

![]()

Faithful Patrons of the Chat ‘n Chew Cafe – (Bob Nielsen)

I have taken many of the articles and publications written these past weeks from Purdue and elsewhere that pertain to the late maturity, high moisture grain, and diseased grain issues of this year’s crops and compiled them into a single collection at the Cafe. I hope this will make your search for such information a little bit more efficient.

<http://www.kingcorn.org/cafe/harvest>

A link to this Web page is also located in the “Current Topics” right sidebar of the main Cafe page. As more articles and publications come out in the coming weeks, I will post them at the Cafe and also add them to the compiled list at the above Web address.

Harvesting, Handling, and Drying Corn with Ear Rots in 2009 – (Richard Stroshine, Professor, Agricultural and Biological Engineering Department)

During the 2009 harvest, growers have reported a significant amount of Diplodia and Gibberrella ear rot in Midwest corn fields. When ear rot is a problem, the corn should be harvested as soon as possible to stop the growth of the ear rot fungi. However, if the problem is severe, check with crop insurance providers regarding adjustments for the damage to the crop. Generally these assessments must be made on standing corn before it is harvested.

Keep in mind that enough drying capacity should be available to quickly dry the corn below 20%. This will ensure Diplodia or Gibberrella ear rots do not continue to grow on the corn when it is in the bin. When harvesting use the maximum capacity of the combine to remove fine material and shrunken, mold damaged kernels. The fine material should be removed because it promotes mold growth and interferes with aeration. Experiment with increasing the fan speed to determine whether this will separate some of the light, severely damaged kernels from the good kernels without removing too many good kernels. Increasing cylinder rpm’s may break up more of the mold damaged kernels, which should be weaker. However, the higher rpm’s will also inflict more damage on the good kernels making them more susceptible to mold growth during drying and storage. Incorporate a screen cleaner into your handling system to remove fine materials not removed by the combine before the corn is placed in the bin. The cleaner may also remove some of the smaller shriveled kernels that have been infected by ear rots.

The best strategy is to dry the corn as quickly as possible below 15% moisture. Once corn is below 20% moisture, there should be no significant growth of Diplodia and Gibberrella in the stored corn. Storage molds including Penicillium, Aspergillus, and Eurotium should not grow when moisture is below 15%, providing the grain is kept below 50°F. Drying to a slightly lower moisture of 14% will be more expensive but will also provide additional protection from mold growth. Do not mix corn with high levels of mold damage with good corn. The dried corn should be cooled below 50°F immediately after drying and eventually cooled to 32 to 35°F if it will be held into the winter. The corn should be marketed or fed to animals (see below) as soon as possible and should not be held until spring. Ethanol plants may reject corn with high levels of mold damage because it will reduce their yields and, if there are toxins present, those toxins can be concentrated by a factor of 3 in the co-products such as DDGS and WDG. These co-products are usually marketed as an animal feed ingredient. While the corn is in storage, keep it well aerated. Inspect the bins regularly so that problems can be detected early.

Before corn is fed to animals it should be tested for mycotoxins. Diplodia does not produce toxins. However, Gibberrella and other ear rots do produce toxins. For information on mycotoxins and testing for mycotoxins check on the website <http://www.grainquality.org> and choose “Extension Publications,” then choose “Diseases and Mycotoxins” and, finally, look for publication BP-47. Some USDA grain inspectors, larger grain elevators, or feed processors have relatively simple and easy to use test kits that can be used for screening samples for mycotoxins. Care must be taken to obtain a representative sample for testing. Animal species differ in susceptibility to various toxins and younger animals are more sensitive. Consult animal science publications for information on feeding corn containing mycotoxins. Additional information on ear rots can be found on the “Diseases and Mycotoxins” tab on <http://www.grainquality.org>.

![]()

Drying Soybeans in 2009 - (Matt Roberts, Grain Quality Specialist, Agricultural and Biological Engineering Department)

The cool and wet fall coupled with a desire to get into the field as soon as possible following rainy weather has many producers throughout the state harvesting soybeans at higher than normal moisture contents. Harvest moistures have been ranging from 10% - 20%. With this wide variation in moisture many growers are questioning what to do, particularly with the soybeans that are above the “safe” storage moisture of 13%. Producers should approach the issue of drying beans with caution. High drying temperatures of 160 – 180°F can lead to excessive seed coat cracking, thus resulting in more splits. Drying will produce fewer splits if the air relative humidity is kept above 40%. For example, if outside air is 60°F with a relative humidity of 80%, it should not be heated above 80°F because when heated to that temperature air relative humidity will be 40%.

Medium temperature drying: In situations where continuous flow dryers or bin dryers are utilized, higher temperatures may be used on high moisture beans. However, soybean exposure should be limited. If seed quality or splits are not a major consideration soybeans may be dried in continuous flow driers at temperatures ranging from 120 -140°F. Exposure to these temperatures should be limited to no more than one-half hour, depending on the initial moisture of the beans. When heat is added to bin dryers, it should be intermittent so that the beans are not exposed to high heat for an extended period of time.

Low temperature drying: Natural air drying is another acceptable means by which to dry soybeans. With adequate ambient temperatures, and lower humidity, 2 -3 points of moisture can easily be removed in a bin. This assumes that the bin is equipped with a drying floor that will produce uniform airflow. Typically 1 to 2 cfm/bu is desirable for natural air drying. Growers should be aware that this process may take up to several weeks to complete depending on the depth of the grain mass. The natural air drying process can be speeded by placing a layer in the bin and drying that layer before the next is added. Another option is to use a bin equipped with stirrers that thoroughly mixes the grain within the bin during drying. Here again, careful monitoring of the bin is important to make sure excessive splits are not occurring, particularly during stirring.

Further considerations: If high moisture beans were added to a bin early and then lower moisture beans where added to the same bin over the next several days, operators should expect the drier beans to eventually pick up moisture. As the air moves through the wet beans at the bottom of the bin it will dry them but then carry the moisture to the grain above. Given enough time, the moisture will be pushed completely through the grain mass.

For more information regarding handling and storage of high moisture soybeans see “Grain Quality Fact Sheet #27 Harvesting, Drying, and Storage of Frost Damaged Corn and Soybeans” at <http://www.grainquality.org>. Click on “Extension Publications” tab and then go to “Drying, Conditioning and Aeration”

![]()

In-Bin Drying of Corn in 2009 – (Richard Stroshine, Professor, Agricultural and Biological Engineering Department)

Late planting combined with the cool summer and poor conditions for field dry down have led to higher than normal harvest moistures for corn throughout the Midwest. Those producers with in-bin low temperature drying systems should use the layer drying procedure. In this approach the corn is harvested in intervals. Initially only enough shelled corn is harvested to fill the bin to a depth of about 3 to 4 feet. The fan is started as soon as enough corn is harvested to evenly cover the drying floor to a depth of 6 to 8 inches with wet corn. If the system is designed to deliver 1 cfm/bu when the bin is filled to a depth of 18 feet, the airflow through a 3 ft layer will be about 12.5 cfm/bu and the airflow through a 4 ft layer will be about 8.4 cfm/bu. This airflow should rapidly remove the moisture from the corn. The time required to dry this first layer will vary depending on the harvest moisture and ambient air conditions. It should be between 1 and 5 days. Monitor the moisture content of the top surface of the corn. When this top surface has dried uniformly to about 20% moisture, another layer can be added. Now there will be 6 to 8 feet in the bin and the airflow through the corn will be 4.7 to 3.2 cfm/bu. It will take longer to dry this second layer, unless the harvest moisture has dropped significantly during the time when the first layer was drying. This procedure is repeated for each successive layer until the bin is full. If more than one low temperature drying bin is available, the time interval between harvests can be reduced by placing a layer in each bin in succession.

Use of heat with low temperature dryers: To minimize drying costs, only use supplemental heat when it is needed. Later when the air relative humidity drops below 60% the bottom 1 to 2 ft. of corn in the bin will be over-dried. When the humidity increases to above 70% later, moisture will be added back to that dry layer. As the over dried corn picks up the moisture from the air, the relative humidity of the air will drop. By the time this air reaches the layer of wet grain, its relative humidity should be back down where it needs to be, below 60%. At the same time, the moisture of the over-dried layer at the bottom of the bin should increase, thereby at least partially correcting the over-drying problem. If there are more hours of relative humidity below 60% than there are hours above 60% in a 24 hour period, supplemental heat may not be needed. However, if a weather front moves through bringing rain and causing the air humidity to stay above 75% throughout the day, then supplemental heat should be used. If the air temperature is between 40 and 70°F and its relative humidity is 90%, increasing the air temperature by 10°F will decrease its relative humidity to 65%. If the initial relative humidity is 80% the 10°F temperature rise will decrease the relative humidity to 55%, and for an initial relative humidity of 70% the 10°F will decrease the air relative humidity to 50%. Supplemental heat can also be used when the daily high outside air temperatures drop below about 45°F or 50°F. At these lower air temperatures, the exchange of moisture between the corn and the air seems to slow down. Keep in mind that if the relative humidity of that 40°F air is below 60% or 70%, the bottom layers of corn will probably be over-dried. Relative humidity often drops during the day and increases at night. Therefore, using supplemental heat in the morning may also be a useful strategy.

Other options: When producers have access to a high temperature dryer or an in-bin batch drying system, it can be used to dry the corn to 19 to 20% before it is placed in the low temperature drying bin where the drying process is finished. High temperature drying is most efficient at the higher corn moistures, so the dryer capacity will be greater and the fuel cost per pound of water removed will be lower. Unless the grain temperature remains above 60°F after it comes out of the high temperature dryer, the mold growth in the 19 to 20% moisture corn will be very slow. If airflow is at least 1 cfm/bu when the bin is full, it should be possible to dry the corn to safe storage moisture before appreciable mold develops. However, the progress of the in-bin drying should be monitored closely and the grain mass should be inspected for signs of mold growth!

In-bin dryers with stirring: In-bin drying systems with stirring devices offer an advantage for wet drying years but they must be operated properly. The stirring almost (but not entirely) eliminates the problem with over-drying and allows supplemental heat to be used effectively because the over-dried kernels are mixed with the wetter kernels eliminating over-drying of portions of the bin. Often the stirrers cannot reach the corn at the very bottom of the bin. That means there will still be a layer of over-dried corn at the bottom. In addition, there is a ring around the outside of the bin that the stirring devices cannot reach. If these systems are used for very wet corn, that layer can begin to mold even when the rest of the corn is at a uniformly low moisture. One solution for the ring of wet corn is to unload the bin and thoroughly mix the corn as soon as the target average moisture has been reached. Drying with stirring is very inefficient once the average kernel moisture reaches 18%. Therefore, it is best to turn off the stirrers when average moisture reaches 18% and finish drying to the target moisture. Then the stirrers can be used for one final stirring to eliminate moisture variations. The producer that has additional drying bins can dry the corn to 18 to 20% moisture in their stirring system and then transfer the corn to another bin to complete drying without stirring.

Removing fine material: There are advantages of removing fine material from corn before it is placed in storage. The fine material is readily available source of nutrients on which molds can grow. Therefore, mold grows more rapidly in wet corn containing fines than in the same corn from which fines have been removed. In addition, the fine material will interfere with air movement through the corn giving uneven air distribution within the bin. That often results in high moisture pockets of grain where mold can develop.

For more information on low temperature drying see Grain Quality Fact Sheet #5 Low Temperature Drying of the 1992 Corn Crop” at <http://www.grainquality.org>. Click on “Extension Publications” tab and then go to “Drying, Conditioning and Aeration.”

BUG SCOUT

"I guess you didn't get around to cleaning this bin!"