Pest & Crop Newsletter

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

What's Happening With the Early Planted Seed?– (John Obermeyer and Larry Bledsoe)

The first thing that came to mind when hearing about producers planting last week is that it will likely be a “good” year for grub and wireworm activity. According to the Indiana Agricultural Statistics Service, 9% of the intended corn acreage is now in the ground. Grub and wireworm damage increases with early planting. Delayed crop emergence and growth will increase the opportunity for these pests to come into contact with and feed-on seedling roots. Wireworm are more tolerant of cool soils are can be quite active early in the season. They are attracted to volatiles given off by sprouting seeds and have the ability to move readily throughout the soil profile. Typically wireworm problems are patchy in a field as they “drill” into seed and seedlings, often causing plant death. Annual white grubs (Japanese beetle our most predominant species) move to the upper soil profile in the spring and feed mostly on decaying organic matter, but will feed-on seedling roots that are nearby. The length of this spring feeding period and grub populations determines if economic damage will occur. In other words, a cornfield planted early where many grubs exist may have significant damage even with a soil insecticide. Grubs feed mainly on the fine roots of seedling plants and occasionally the mesocotyl. Root feeding may lead to stunted and/or discolored seedlings, mesocotyl damage will likely cause plant death. Producers who find grubs should collect several to take to their county extension educator, crop consultant, or agriculture chemical/fertilizer dealer for positive identification. Species identification will determine whether this is an annual grub or the true white grub that may be in the soil for another season or two. Late April and early May corn planting reduces the chance of economic wireworm and grub damage. Since rescue treatments are not available, the most effective way to control these pests in corn is to apply a soil insecticide at planting. If wireworm and/or grub populations are observed in a cornfield that has already been planted and the stand is threatened, a soil insecticide should be used as part of a replant operation providing the pests are still present. Replanting, however, is not recommended unless a critical level of plants is being significantly damaged or destroyed. Remember that a number of factors can cause stand reductions. If a stand is declining, determine if the grubs or wireworms are still actively feeding before making a replant decision. If planting very early to soybean, consider that no at-plant soil insecticides are registered and altering cropping rotations may be needed. Delaying soybean planting to mid May is an effective management option. The following chart may help when making replant decisions. For example, corn planted on April 25 but with only 16,000 plant per acre because of wireworm/grub damage, is at 86% optimum yield. Replanting on May 21 and obtaining a population of 25,000 plants per acre should increase your optimum yield approximately 10%. One must consider factors such as seed and machinery costs, hybrid maturity, and extended weather forecasts before replant decisions are made.

Black Cutworm, Pheromone Trapping, and Predictions– (John Obermeyer and Larry Bledsoe)

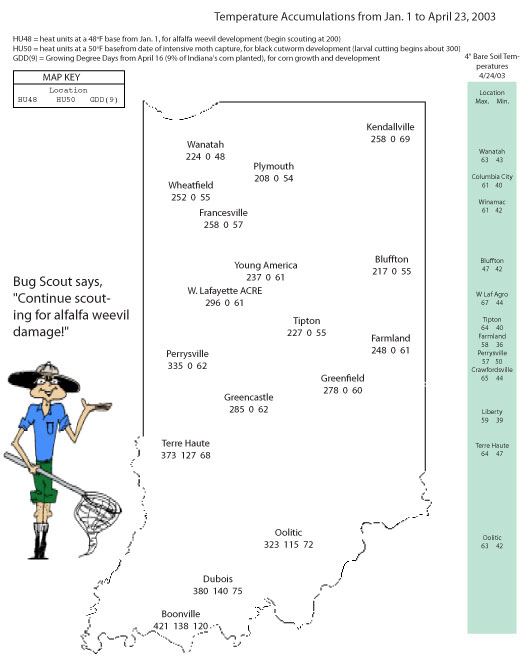

Those observing the weekly “Black Cutworm Adult Pheromone Trap Report” should have noted that some of our cooperators have been busy counting black cutworm moths in their traps. A few high counts, known as intensive captures, have been reported in several locations since the first week in April. Surrounding states that have similar monitoring programs have reported much the same. Now that black cutworm moths have arrived in Indiana and corn planting has begun, what is the sensible pest management approach? Refer to the “Weather Update” of this newsletter, where we are tracking heat unit accumulations for insect development, corn growth, and soil temperatures. HU50 is the temperature we use to track the development of the black cutworm from the time of an intensive capture to first cutting/damage. Based on the growth development model, it takes approximately 300 heat units (50?F base) from egg hatch to early 4th instar; this is when black cutworm larvae begin to cut plants. Some leaf injury may be present before then. Using pheromone trapping of moths and tracking of heat unit accumulations for first cutting is not an exact science, but they do give us a good indication of what to expect. It is not possible to predict if individual fields will be infested.

Unfortunately many agricultural insecticide suppliers will use this information as an opportunity to increase insecticide sales. Some producers will support their cause by buying and applying products that are not needed. There are two ways cutworms can reduce your profits, excessive cutting of young plants and unnecessary insecticide applications. Without a doubt producers are losing money if they are routinely applying prophylactic insecticide treatments for black cutworm. They should only be used where they are needed! Field scouting is the most efficient and economical way to deal with the black cutworm. Study after study has shown that planting-time insecticides are not as effective as rescue/foliar treatments for cutworm control. Scouting will also reveal that even during a “bad” cutworm year, that less than 5% of the fields have reached economically important levels of infestation. Another consideration is that field scouting often reveals that only a portion of a field needs to be treated. Again, don’t anticipate black cutworm problems with an at-planting insecticide application. Continue to watch the “Weather Update” to determine when to better time your scouting trips, and watch for further cutworm developments throughout the spring season and threshold/control information in future issues of the Pest&Crop.

Alfalfa Weevil, Slow but Steady– (John Obermeyer and Larry Bledsoe) Ron Blackwell’s weevil surveys in central Indiana counties reveal that larval activity has picked up a little, even with the cooler temperatures (see “Alfalfa Weevil Larval Survey”). This damage is nothing to what we’ve seen in the last several years with this pest, but don’t be lax in your field surveys and evaluations. Producers in southern and central counties should continue to monitor fields for weevils and determine the percent tip feeding. Controls, however, should not be applied until thresholds are reached (see Pest&Crop #4, April 11, 2003) at approximately 400 HU (48?F base) or above. The exception is that after 300 HU have accumulated if 3 or more larvae are noted per stem and percentage tip feeding is above 50%. In this case, a field will need to be treated immediately with a residual insecticide.

Click for Table.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Marestail- Will it Be a Problem This Year?- (Bill Johnson, Glenn Nice, and Tom Bauman) Last summer, there were a number of product performance issues related to poor herbicide activity on marestail There are a number of reasons why this occurred and the purpose of this article is to provide an overview of these reasons and an update on the current status of marestail in Indiana. Reasons why marestail was difficult to control in 2002:

The Good News. Our observations so far this year is that the marestail populations are lower than they were last year. There are a number of reasons for this.

So, to answer our question above, it appears that the marestail problems are of a lower magnitude so far this year. But weather conditions which prevent spraying and/or soil preparation over the next couple of weeks could result in a different story. Stay tuned…. Final Comment. Weed Scientists at Purdue University are very concerned about this issue and will be monitoring the distribution and spread of glyphosate-resistant marestail in Indiana. If you think you have a suspect population, please contact your county Extension Educator. We will be collecting seed later this summer and fall from across the state for glyphosate tolerance screening and would to collect seed from as many populations as we can manage.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corn Segregation: A Necessary Evil in Today’s Biotech Age? - (Bob Nielsen) The recent approval by the US EPA (2003) of the new rootworm-resistant Bt corn technology raises again the important issue of corn segregation or identity-preservation for the purpose of minimizing uncertainty in the marketplace. This latest plant-incorporated protectant for corn, developed by Monsanto™, is referred to as the YieldGard® Rootworm trait and contains the “MON 863" transgenic event that results in the production of the Bt protein known as “Cry3Bb1." Contrary to the earlier marketed Bt traits, this one targets the pesky corn rootworm insect rather than the European corn borer. There is no question that many Indiana corn growers have been waiting impatiently for this new transgenic trait and are eager to test out hybrids containing this trait. Supply of hybrid seed for the 2003 season is rather limited, but will increase markedly in coming years. As with some other transgenic corn traits (e.g., Herculex® Bt, Roundup Ready®, most Bt/RR stacked hybrids), Indiana growers need to temper their enthusiasm with the recognition that the MON 863 trait has not received global approval in the marketplace, especially with the European Union (EU). Consequently, some grain buyers may not be willing to purchase grain of these transgenic hybrids or non-transgenic grain that contains detectable levels of transgenic contamination. It will be imperative for growers of the new Bt hybrids to identify buyers who will accept the grain at harvest time. The intentions of major grain buyers regarding acceptance of grain from hybrids not yet approved by the EU is available on the Web (National Corn Growers Assoc, 2003). In addition, the American Seed Trade Association (2003) maintains a grain buyer database that helps growers identify “grain handling facilities that have indicated a willingness to purchase, receive, and handle genetically enhanced corn products that have full U.S. registration for food and feed use, but are not yet approved for import into the European Union.” As with the earlier Bt traits, production of corn hybrids with the MON 863 event will require planting a non-Bt corn hybrid as a refuge to minimize genetic selection pressure on the pest that may otherwise result in the development of pest resistance to the Bt protein (Monsanto, 2003). The refuge design is similar to that for Bt corn borer hybrids, but may change in the future. According to the US EPA, “A 20% non-Bt corn refuge is sufficient for a 3 year interim period while additional information is being gathered. The non-Bt corn refuge should be planted as continuous blocks adjacent to the MON 863 fields, as perimeter strips, or as non-transgenic strips planted within the transgenic field. A 20% non-Bt corn refuge is necessary to produce an adequate number of CRW susceptible to the Cry3Bb1 protein. Considering the limited movement of CRW larvae, planting refuges close to transgenic fields in large blocks is preferred to narrow strips. If a 20% refuge is planted as row strips within a corn field, then the strips must consist of at least 6 to 12 consecutive rows.” This lengthy introduction finally leads to the important issue of grain segregation for the express purpose of keeping grain of non-transgenic hybrids (or transgenics with full market approval) segregated from grain of transgenics that may require delivery to specific buyers. The US EPA is requiring that Monsanto make available Cry3Bb1 strip tests to grain handlers by September 2003. These qualitative tests will be used by some buyers to detect the presence of the Bt protein in loads of grain that are purportedly not from MON 863 fields. Successful segregation of transgenic and non-transgenic grain includes a number of factors. The most commonly talked about factor is the risk of pollen drift from transgenic corn fields to non-transgenic corn fields. Two recently published on-line newsletter articles address this issue (Gray, 2003; Thomison, 2003), so I won’t spend much more time discussing it. Simply recognize that while it is true that the overwhelming majority of a corn field’s pollen load likely drops very close to the source field, experience also tells us that small amounts of pollen can travel a quarter mile or greater and still remain viable (Burris, 2002). Thus, prudence dictates that growers be aware of what is being grown in adjacent fields, monitor the calendar dates of pollination among those fields to determine the risk of cross-pollination, and take appropriate steps at harvest time if necessary to separately harvest and segregate grain along field edges within several hundred feet of a possible contaminant field (Nielsen & Maier, 2001). Other factors important to successful grain segregation include planter hygiene, harvesting hygiene, transport hygiene, and grain handling hygiene (Maier & Nielsen, 2001). The key consideration here is to identify and eliminate all opportunities for seed or grain commingling between transgenic and non-transgenic hybrids throughout the entire production cycle. Follow the principle of First-In-Field, First-Out-Field (FIF-FOF). This means that fields of non-transgenic varieties should be planted first to avoid transgenic seed commingling with non-transgenic seed in the nooks and crannies of the planter. Similarly, the non-transgenic fields should be harvested first in the fall before transgenic fields in order to avoid transgenic grain commingling with non-transgenic grain from the nooks and crannies of the combine. Obviously, the planter and combine should be thoroughly cleaned of remnant seed or grain from previous years prior to their first use this season. Following the FIF-FOF principle will facilitate proper hygiene of the transport, drying, and grain handling activities also.

Pay Attention to Management Needs of Fertilizer Products- (John Sawyer, Iowa State Univ., Orig. Published 4/14/03, Integrated Crop Management Newsletter, Iowa State Univ.) With concerns this spring about nitrogen (N) fertilizer availability and pricing, perhaps you are considering an N product you haven’t used before. What management considerations should you pay attention to? When properly managed, all N fertilizers can be effective for supplying crop N needs. Anhydrous Ammonia

Urea

Urea-ammonium nitrate solutions (UAN 28 or 32 percent N)

Other N fertilizers

Early-Planted Corn & Potential for Freeze Injury - (Bob Nielsen) - Corn planting began in some parts of Indiana during the past couple of weeks. As of 20 April, the USDA-NASS estimated that 9% of the state’s corn acreage was already planted. Periods of reasonably warm soil temperatures have encouraged germination of corn and some fields may be approaching emergence or beyond. Such early planting of corn is always accompanied by the risk of injury by frost events or lethal cold temperatures. Of these two risk factors, lethal cold temperature is the more worrisome one since a corn plant’s growing point region is relatively protected from the effects of simple frost while it remains below the soil surface. Lethal cold temperatures (28F or less) can penetrate the upper inch or two of soil, especially dry surface soils, and kill plant tissue directly, including growing points. Non-lethal injury by cold temperatures may cause deformed elongation of the mesocotyl or physical damage to the coleoptile, resulting in a “cork-screw” symptom and subsequent leafing out underground. Air temperatures in some areas of Indiana dipped to potentially lethal levels for several hours early in the morning of 23 April. In many other areas, temperatures were easily in the low 30’s F. Given the risk of chilling injury to young corn; it would behoove growers to monitor early-planted fields for stand establishment problems. It wouldn’t be surprising if some fields, or areas of fields, will eventually require replanting due to lethal or sub-lethal injury from cold temperatures. Don’t forget, this and other timely information about corn can be viewed at the Chat ‘n Chew Café on the World Wide Web at http://www.kingcorn.org/cafe. For other information about corn, take a look at the Corn Growers’ Guidebook on the World Wide Web at http://www.kingcorn.org/.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||